Shearing Machine

TMA is the leading manufacturer of Plate Bending machines in China: a strong brand, a leader in technical innovation and customer service, with a global footprint. Today TMA is able to satisfy any type of request for the design and production of a Plate Rolling Machine and Plate Bending Machine: useful width from 200 mm up to 8000 mm and thickness from 0,5 up to 300 mm. We offer a complete selection of metalworking equipment, 2, 3, and 4 rollers bending machines, profile bending technology, straightening machines for convex bottoms, and finally, digital CNC systems with customized software.

High Performance Fiber Laser Cutter from TMA

The plate rolling machine is a kind of equipment that uses work rolls to bend sheet metal. It can form parts of different shapes, cylindrical and tapered. It is essential processing equipment. The working principle of the plate bending machine is to move the work roll through the action of hydraulic pressure, mechanical force, and additional external parties to make the plate bend or bend into shape. According to the rotation, movement, and position changes of work rolls of different forms, the plate rolling machine can process parts such as the oval, arc, and cylindrical elements.

Swing Beam Shears adopts high technology standards, design, and a user-friendly interface. We have reduced the cutting angle to achieve straight precision and minimum twist tolerance. QC12K Hydraulic Shearing Machine provides perfection with high-standard safety and efficient solutions that strengthen your skills and add value to your company.

Swing Beam Shears adopts high technology standards, design, and a user-friendly interface. We have reduced the cutting angle to achieve straight precision and minimum twist tolerance. QC12K Hydraulic Shearing Machine provides perfection with high-standard safety and efficient solutions that strengthen your skills and add value to your company.

FAQ

What is Hydraulic Guillotine Shears?

The gate-type shearing machine uses a frame structure with all-steel welding. It has four angles, eight sides with a right-angle guide rail, high precision, good rigidity, and hydraulic pre-tightening. The whole hydraulic system adopts a two-way cartridge integrated valve and can be configured with a digital stroke display, photoelectric protection device, and portable table (convenient for changing the mold). The gate-type shearing machine has a double function of both the upper slider and the lower hydraulic pad, and the device can adjust the working pressure stroke in the specified range according to the process requirements. It is easy to operate with the centralized control button.

The gate-type shearing machine uses a frame structure with all-steel welding. It has four angles, eight sides with a right-angle guide rail, high precision, good rigidity, and hydraulic pre-tightening. The whole hydraulic system adopts a two-way cartridge integrated valve and can be configured with a digital stroke display, photoelectric protection device, and portable table (convenient for changing the mold). The gate-type shearing machine has a double function of both the upper slider and the lower hydraulic pad, and the device can adjust the working pressure stroke in the specified range according to the process requirements. It is easy to operate with the centralized control button.

What are the Function features of Hydraulic Guillotine Shears?

- Use the whole welding frame structure and vibration aging treatment. The machine has good rigidity, high precision, and good precision retention.

- Use a three-point supporting axle rolling guide rail. The upper tool rests and moves gaplessly in the rolling guide rail. Rotating the hand wheel can adjust the service life of the blade.

- The movable blade support and four-legged long blade are provided for easy adjustment of blade gap uniformity, improve shear quality and prolong blade service life.

- Use a tandem cylinder synchronization system. The machine is forced uniformly. Adjusting the flow of the tandem cylinder makes it very convenient to adjust the shear angle, which can meet the needs of different shear plate thicknesses.

- Use a motorized rear stopper device and electronic counter. It is convenient to adjust the position of the rear stopper.

What is Swing Beam Shearing Machine?

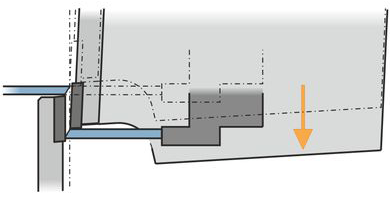

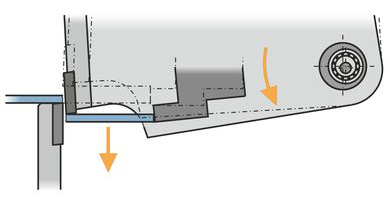

The swing-type shearing machine usually adopts inclined blade shearing. It has been widely used because of its simple structure, low failure rate, high shearing efficiency, and no distortion and warping after cutting. In the shearing process, as the tool rest does rotary movement, the angle and shearing gap of the swing-type shear will change.

The swing-type shearing machine usually adopts inclined blade shearing. It has been widely used because of its simple structure, low failure rate, high shearing efficiency, and no distortion and warping after cutting. In the shearing process, as the tool rest does rotary movement, the angle and shearing gap of the swing-type shear will change.

The machine is a steel-welding structure. Hydraulic transmission, vibration to eliminate stress, and it has high strength and good rigidity. Hydraulic swing-type shearing machines do downward shearing movement, and nitrogen cylinder return by using the main cylinder (fixed on the wall panel). So simplified, the hydraulic system operates more stably—the upper tool rest of the swing-type shearing machine swings around a fixed axis in the shearing process. Through leverage, the fulcrum has little force, which can improve the shearing blade and machine life. The whole machine is in a compact structure and can electrodeless adjust the stroke of the upper tool rest, significantly improving the working efficiency.

What are the Function features of Swing Beam Shearing Machine?

The shearing machine, to obtain a high-quality workpiece, should be able to ensure the straightness and parallelism of the shear surface of the sheet after cutting and minimize plate distortion. The upper blade is fixed on the tool rest, and the lower is specified on the working table. Material supporting ball is set on the operating table, so the sheet material will not be scratched when sliding on it. The rear stopper is used for plate positioning, and the motor adjusts the position. The press cylinder compresses the sheet to prevent it from moving during shearing. The guardrail is a safety device to prevent accidents at work. The return usually depends on nitrogen, which is fast and has little impact.

Leave a message online

If you are interested in our company's products, please fill in the relevant information on this page and submit. A staff member will contact you in time, or please call us directly.