Hydraulic Press

JW36 Series Straight-side Two Point Press

JW36 Series Straight-side Two Point Press, high -tech boutique created by TMA Machine, with excellent performance and stable quality, lead the industry's new style. The machine is designed with a four -pillar straight wall rack, which is symmetrical before and after, and the variable volume is extremely small. It can still maintain high accuracy to ensure that long -term use can be maintained. Steel plate welding the fuselage, no high -open throat disadvantage of traditional C -shaped machine tools, has the characteristics of high strength, high stiffness, and high precision, which provides strong support for your continuous mold processing. The perfect combination of the dual crankshaft reverse transmission and the anti -bias guide rail has greatly improved the anti -load capacity of the machine tool to ensure that it can run stably under various complex conditions. The slider adopts four corners and eight -sided long guide, which is accurate to meet your ultimate pursuit of high precision. The application of high -torque wet friction clutch makes the machine's work stable, small noise, and long service life, bringing tranquility and comfort to your production environment. Electric modeling function, the reading is accurate to 0.1mm, allowing you to easily control every detail. In addition, the JW36 closed double -point pressure machine is also equipped with a centralized lubrication system and a circular indicator device to ensure that the equipment is lubricated and extended the service life. Multifunctional electronic electronic control system, high security, escort your production. What's more worth mentioning is that the JW36 closed dual -point pressure machine can be equipped with various automated peripheral equipment, greatly improving production efficiency, and let your production lines rejuvenate.

Introduction to Configuration

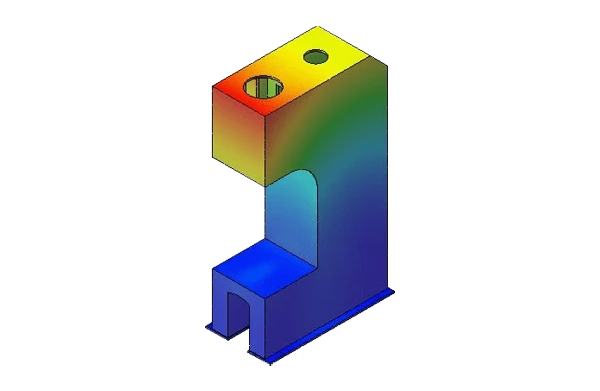

FEA & Stress Analysis

Stress Analysis & Finite Element Analysis

The CAE software SOLIDWORKS used as the method to analyze the linear static construction, stress and deformation for press break and laser cutting machine frames. So for complicated structures, highly complex loading’s, transient modelling and combination of the above, FEA makes sense.

STRUCTURE AND TABLES

Y41B-series C-frame presses consist of an electro welded structure made solely of S355JR steel. They are stabilised and machined at the end of the structural welding process to ensure perfect parallelism and precision. Calculated and designed by finite. With all this, we always guarantee our high precision and quality standards. These models are equipped with a mechanized lower and upper C45E steel table with DIN-650 grooves. The upper table ensures perfect alignment by means of two cylindrical lateral guides of 50 mm diameter with maintenance free anti-friction bimetallic caps.

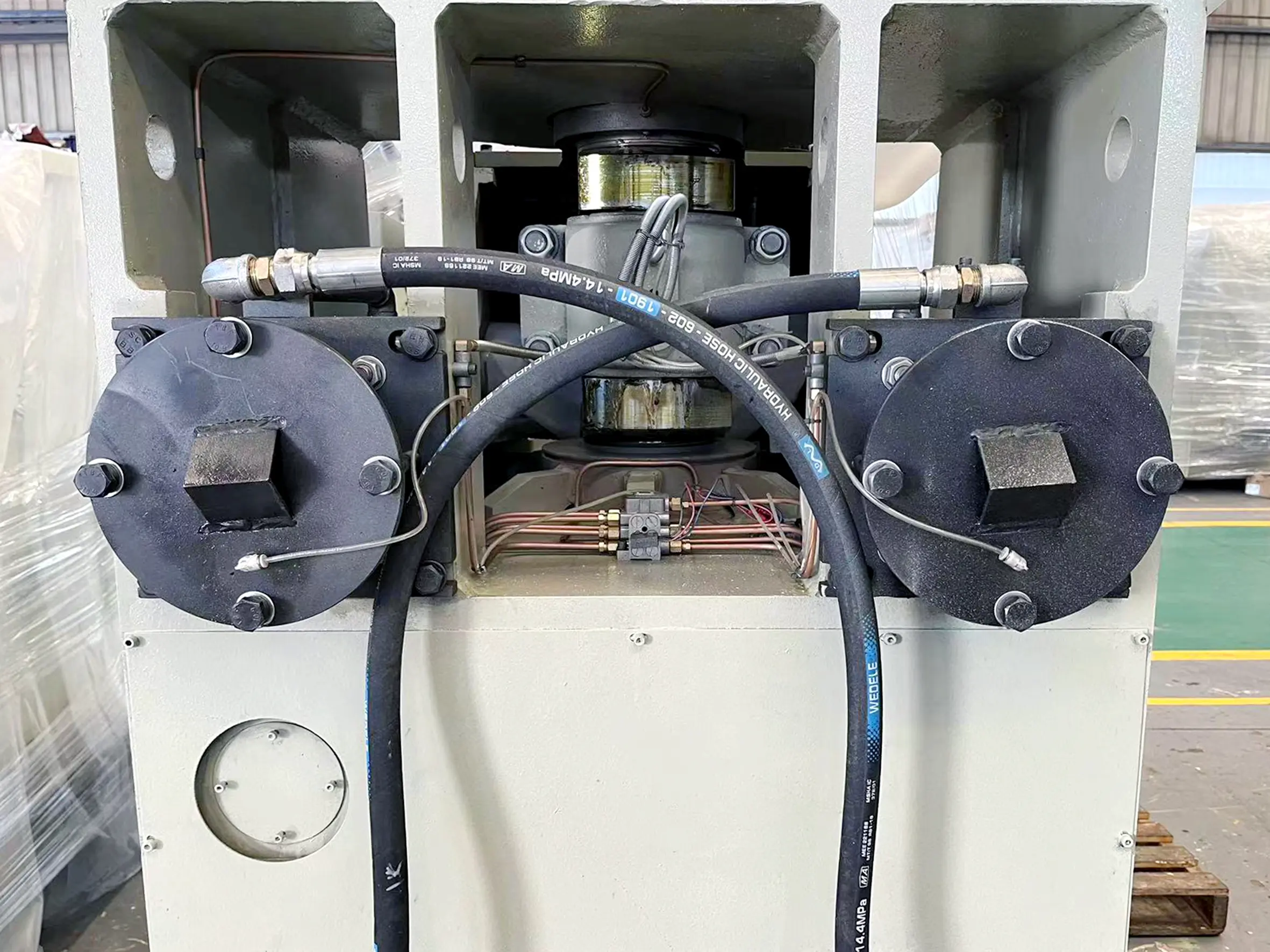

CYLINDER AND HYDRAULIC UNIT

The cylinder is double acting with a chrome plunger and maintenance-free anti wear guides. Anti-turning of the cylinder with a squared front ant stroke endings come as standard which enable us to conveniently regulate the cylinder stroke.

A two-speed motorized hydraulic unit with automatic high speed deactivation. It’s equipped with a cylinder decompression valve. A pressure switch placed at the lateral part comes as standard which allows the regulation of the most appropriate pressure signal for each kind of pressing.

They are supplied with a glycerin gauge with reading in tonnes.

ELECTRIC INSTALLATION AND SAFETY

The control panel features a switch enabling the user to select the desired type of work in a manual, semi-automatic or automatic position and a switch to select either the fast speed or slow speed. Electrical and hydraulic manoeuvres are redundant and self-controlled. They incorporate an additional safety block and self-control devices for manoeuvre and safety. It includes the verification and certification of the correct operation and the safety distance for the photocells.

Operation is carried out by low voltage electric pedals.

Safety is guaranteed by the use of two lateral protections and with level IV safety light curtains situated at the front.

They allow the installation of a hydraulic cushion or a hydraulic ejector. They are supplied with an instructions manual.

It meets and satisfies all the essential health and safety requirements in accordance with the EC standard.

Standard Equipment

REQUEST INFORMATIONStandard Equipment

Mitsubishi - Japa

Main Motor: Siemens Motor - Germany

Foot Switch: KACON - South Korea

Sealing Ring: PARKER - America

Electrics: Schneider Electric - France

Foot Switch: KACON - South Korea

Oil Pump: Sunny - USA

High Efficiency Motor - Class IE3

Technical Parameter

| Name Model | Unit | Y41B-4T | Y41B-6.3T | Y41B-10T | Y41B-16T | Y41B-25T | Y41B-40T | Y41B-63T | Y41B-100T | Y41B-160T | Y41B-200T | Y41B-250T | Y41B-315T | |

| Nominal force | KN | 40 | 63 | 100 | 160 | 250 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | Nominal force | |

| Maximum working pressure of liquid | Mpa | 8 | 8 | 8 | 13 | 20 | 23 | 25 | 26 | 25 | 25 | 25 | 25 | |

| Maximum opening height | mm | 390 | 450 | 500 | 550 | 600 | 700 | 800 | 800 | 900 | 900 | 900 | 900 | |

| Maximum stroke of slider | mm | 200 | 250 | 300 | 350 | 350 | 400 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Slide down speed | mm/s | 45 | 45 | 45 | 45 | 45 | 49 | 35 | 25 | 20 | 20 | 20 | 20 | |

| Slider return speed | mm/s | 75 | 85 | 75 | 75 | 100 | 85 | 68 | 54 | 59 | 70 | 70 | 70 | |

| Deep Throat | mm | 160 | 220 | 220 | 280 | 280 | 300 | 320 | 320 | 325 | 325 | 325 | 325 | |

| Working desk size | F.B. | mm | 420 | 420 | 480 | 480 | 550 | 600 | 600 | 600 | 600 | 600 | 600 | 800 |

| L.R. | mm | 460 | 460 | 550 | 550 | 700 | 800 | 800 | 1200 | 1200 | 1200 | 1200 | 1200 | |

| Height of working platform from ground | mm | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 800 | 800 | 900 | |

| Blanking aperture | mm | 70 | 80 | 80 | 80 | 80 | 100 | 120 | 120 | 100 | 200 | 200 | 200 | |

| Motor Power | KW | 2.2 | 3 | 4 | 4 | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | |

| Machine size | E.B. | mm | 1080 | 1080 | 1220 | 1280 | 1280 | 1470 | 1500 | 1550 | 1650 | 1700 | 1700 | 1750 |

| L.R. | mm | 620 | 650 | 730 | 755 | 755 | 1250 | 1400 | 1400 | 1400 | 1600 | 1800 | 1800 | |

| Height above ground | mm | 1725 | 1900 | 1990 | 2100 | 2100 | 2450 | 2650 | 2650 | 2760 | 2700 | 2700 | 2850 | |

| Total weight (approximately) | T | 0.7 | 1 | 1.5 | 1.5 | 1.5 | 3 | 4.5 | 5 | 6.5 | 8 | 10 | 12 | |

Product Video

Related Products

Service Advantage

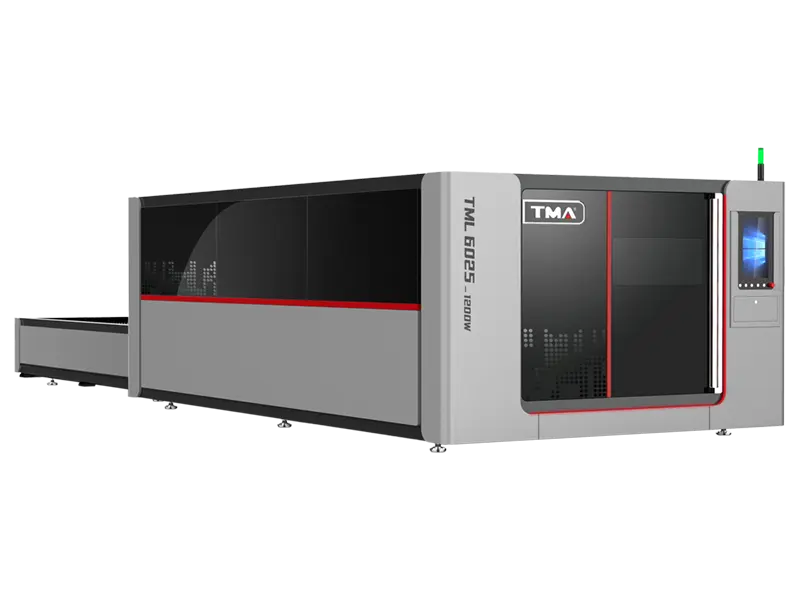

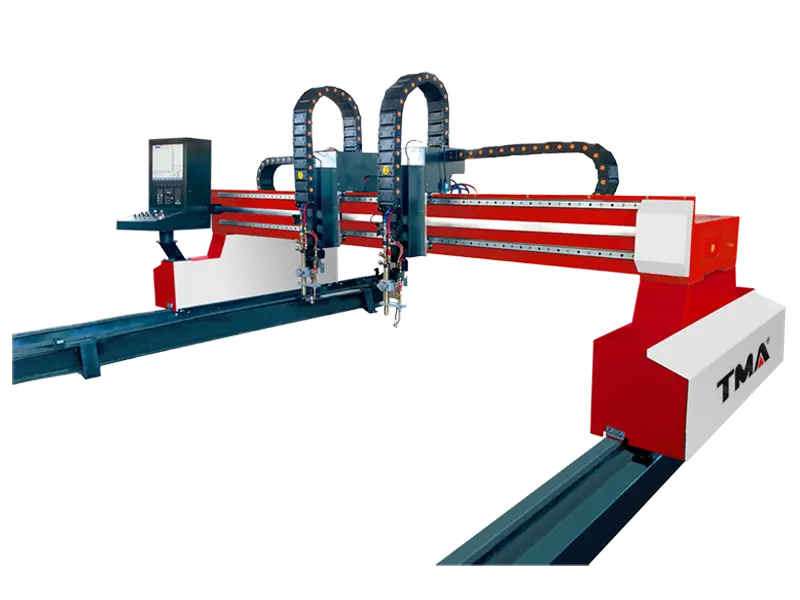

Excellent Processing Equipment

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Tailor-made Solutions

According to your needs and circumstances, reasonable complete equipment solutions and knowledge training can be customized for you.

Super Cost-effective

The company has excellent production environment conditions, complete production process equipment, mature production and manufacturing system, and rich production and manufacturing experience.

Perfect After-sales System

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Qualification

Leave a message online

If you are interested in our company's products, please fill in the relevant information on this page and submit. A staff member will contact you in time, or please call us directly.