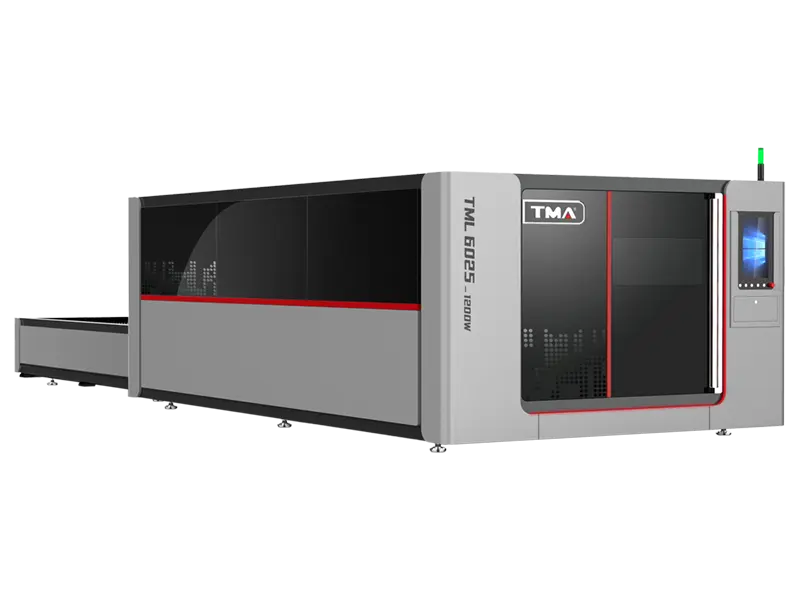

Plasma Machine

Table Type Plasma Cutting Machine

P-Series plasma cutting machine is used for cutting thick metals. The Hypertherm cutting head is a reliable and robust plasma source. Together with the CNC control unit and power source provides precise and high-quality cutting. P-Series plasma cutting machine is designed for precision cutting, High Performance, and High Speed. It can be equipped with Pipe cutting, a 5-Axis beveling head, multi-plasma heads, and Oxy cutting heads.

Introduction to Configuration

BEVELING HEAD (5-Axis)

TMA 5-Axis beveling head is designed for 3D and angle cutting. Up to 45° all the angles are calculated automaticly and created so the operator can input the desired angles as needed. Also the straight vertical cuts can be done, reduced maintenance due to height detection sensor.

- Automatic angle adjustment

- Time saving – short setting time

- Excellent cutting and contouring

- Low production costs

- Offers bolt hole quality

OXY CUTTING

TMA CNC Controlled plasma cutting machines also provide oxygen cutting capability. With our oxygen head equipped machines up to 200 mm cut can be done and this limit can be increased with special design options.

Plasma Cutting

The TMA Plasma series uses Hypertherm’s patented technologies for quality, more power, more precision and more consistent cutting.

- Power Pierce: Repels molten metal during piercing allowing strong production piercing

- Long Life: Gas intake and flow rate is adjusted under contol.

- High Definition: Aligns and focuses the arc, superior quality and consistent cutting

- High Definition: Delivers increased arc density and cut speeds while maintaining arc stability and smoother cut edges.

- Increases number of cuts per hour

- Decreases cost per cut

Hypertherm Power Source

Efficiency, fast cutting, fast processing cycle provides high reliability with easy replacement of consumables. Advantages: Superior cutting quality, minimum operating cost and maximum productivity.

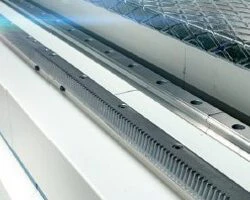

Rack Pinion And Linear Guiding

High precision cutting achieved with dual guiding system Rack Pinion and Linear Guides.

Cable Tray Carriers

Cable channels in accordance with CE standards, silent operation, durability, With its anti-friction and non-breaking properties usage life is much longer.

Partial Pneumatic Suction System

With the PLC software, pneumaticly controlled hatches which are only at the cutting area are opened. With this way more powerful suction with less energy consumption can be achieved.

CNC Control Uniy ESA / Hypertherm

Thanks to its easy operation, plasma processes can be efficiently and easily managed.

Standard Equipment

REQUEST INFORMATIONStandard Equipment

Hypertherm Power Source

Automatic Torch Height Control (Sensor THC)

CAD/CAM Software

Hypertherm Auto Gas control unit

Bridge driven with Servo Motors on both sides X Axis

Precise helical rack, pinion and linear dual guiding

CNC controled outputs/inputs for vacum table & filtering unit

Positioning accuracy +- 0,1 mm

Positioning speed 40 m/min

Torch collision sensor

Independent bridge and cutting table design

Optional Features

Hypertherm Edge Connect /TC CNC Unit

Other Hypertherm power source options

Auto Gas Console options

Lantek CAD/CAM software, automatic nesting

Hypertherm Pronest CAD/CAM software

Filter Unit

Consumables starter kit

5-Axis cutting head

Double bridge

Pipe cutting

Oxy cutting head • Tanaka Oxy Torch • Messer Oxy Torch

Multi Plasma heads

True Hole

Technical Parameter

|

P-Series Plasma Cutting |

Cutting Width |

Cutting Length |

Table Height |

Height |

Width |

Length |

Width (Including Power Unit) |

Length (Including Filter) |

Filter Height |

Filter Length | |

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

J | ||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm | ||

| A1500 |

3000 |

1500 |

3100 |

650 |

2000 |

2320 |

4500 |

5500 |

6500 |

2200 |

2000 |

|

4000 |

1500 |

4100 |

650 |

2000 |

2320 |

5500 |

6000 |

7500 |

2200 |

2000 | |

|

6000 |

1500 |

6100 |

650 |

2000 |

2320 |

7500 |

6000 |

10000 |

2200 |

2500 | |

|

A2000 |

6000 |

2000 |

6100 |

650 |

2000 |

2820 |

7500 |

6500 |

10000 |

2200 |

2500 |

Product Video

Related Products

Service Advantage

Excellent Processing Equipment

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Tailor-made Solutions

According to your needs and circumstances, reasonable complete equipment solutions and knowledge training can be customized for you.

Super Cost-effective

The company has excellent production environment conditions, complete production process equipment, mature production and manufacturing system, and rich production and manufacturing experience.

Perfect After-sales System

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Qualification

Leave a message online

If you are interested in our company's products, please fill in the relevant information on this page and submit. A staff member will contact you in time, or please call us directly.