Plasma Machine

TMA Machine's plasma cutting machine is a high -tech equipment using high -temperature and high -speed plasma airflows for cutting. It breaks through the limitations of traditional cutting methods, and meets the urgent needs of high -precision and high efficiency in modern industry with faster, more accurate, and more stable characteristics. Our plasma cutting machine uses the most advanced plasma technology to easily cut various metal materials. Whether it is hard steel or fragile aluminum alloy, it can be eased.

In the fierce market competition, TMA Machine's plasma cutting machine has won the favor and praise of customers with its outstanding performance and unique design. It is not only your ability to improve production efficiency and reduce costs, but also an important tool for you to show the strength of the enterprise and enhance the brand image.

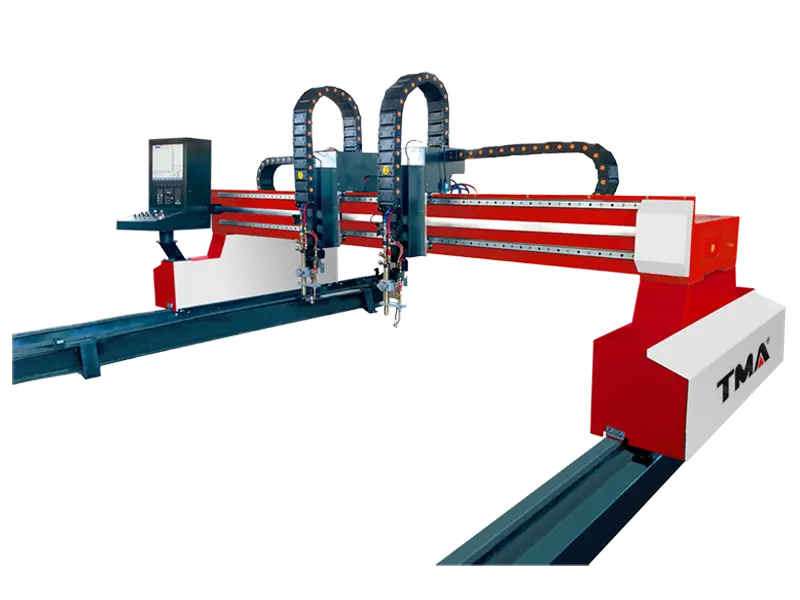

Plasma Cutting Machine

The airflow of high -temperature plasma is scratched like lightning, and the metal material is divided into the shape of your heart in an instant. This is the magic of the TMA Machine plasma cutter. With cutting -edge technology, it can easily control various metal materials and cut out unparalleled accuracy and speed.

Our machine is not only powerful, but also smart. The intelligent control system is like a superb craftsman, which can accurately guide the cutting process. Whether it is a complex curve or a fine pattern, it can be easily completed. You just need to gently give it to it!

At the same time, we know the importance of environmental protection and energy conservation. Therefore, the TMA Machine plasma cutting machine uses advanced energy -saving design to ensure that while working efficiently, it also minimize the burden on the environment as much as possible. Make your production greener and sustainable.

Choosing TMA Machine plasma cutting machine is to choose innovation, efficient and future. We firmly believe that the power of technology can promote the progress of industrial manufacturing, and TMA Machine is the leader of this power. Let's use the sharp blade of technology to cut out a better future!

P Plasma Cutter Machine

Table Type Plasma Cutting Machine

P-Series plasma cutting machine is used for cutting thick metals. The Hypertherm cutting head is a reliable and robust plasma source. Together with the CNC control unit and power source provides precise and high-quality cutting. P-Series plasma cutting machine is designed for precision cutting, High Performance, and High Speed. It can be equipped with Pipe cutting, a 5-Axis beveling head, multi-plasma heads, and Oxy cutting heads.

P-C Plasma Cutter Machine

Oxy Plasma Carbon Steel Cutting Machine

TMA designed the plasma-oxygen carbon steel cutting machine using modern construction and mechanics solutions. They ensured the best efficiency and an attractive, innovative look. Modified bridge construction makes it more rigid and resistant to high temperatures. It is essential, especially during even 300 mm thick materials cutting. The unique combination of safety systems used in plasma-oxygen carbon steel cutting machines ensures the highest comfort and the best level of safety for machine operators and the people around them.

FAQ

What is TMA Plasma Cutting Machine Technology?

TMA plasma cutting benches offer different cutting options with plasma power supply options according to the needs of their customers. Helical rack gear, pinion and reducer are used, providing precise positioning and silent operation. The cutting table, with its horizontally and vertically separated suction sections, provides suction control at the highest capacity and removes dust and particles in the environment. The motor driver group is one of the leaders of the market, and it minimizes the need for service. TMA Plasma Cutting Machines have their own user panel. In this way, it understands the customer’s needs in the best way and provides a fast and efficient use.

Why Should You Choose TMA?

Business, like life, is a journey. With TMA machines, you will overcome all obstacles and surmount all challenges that business presents. We will be with you every step of the way. We know that your growth is our growth, and that your success is our success. As TMA, we manufacture machines that are durable, flexible and innovative. We aim for excellence in all our machines. We build trust with our customers and produce flawless tools. Our cutting-edge technology will get you clear-cut results, fast, with perfection. With TMA you will progress and produce continuously.

What Are the Advantages of Plasma Cutting Machines?

One of the main advantages of a plasma cutting machine is the variety of its applications. They can be used to cut metal in various thicknesses. Their applications vary from retail product design to industrial equipment. Secondly, having a plasma cutting machine will increase your production capabilities. Moreover, it will render your business independent. You won’t need to outsource your punching needs. This will save you money, time, energy and manpower. Thirdly, a sturdy and durable plasma cutting machine will increase your production. These machines are designed for consecutive uses. You can use your machine many times, without interruption to your production line. TMA Machine Plasma Cutting Machines are durable. They will be with you for long and productive years. You will save time, energy and manpower due to our cutting-edge technology. Our R&D team continuously works to ensure that your machine is the best the market has to offer. Moreover, you will benefit from TMA Machine after-sales services, we will be with you every step of the way.

How Do Plasma Cutting Machines Work?

Plasma cutting uses an accelerated jet of hot plasma to cut conductive materials. They use a conductive gas with a temperature of up to 30,000°C. Plasma cutting operates by creating an electrical channel of superheated, electrically ionized gas. This is called the plasma. Plasma machines perform cutting by using a horizontally moving cutter plasma head on the fixed sheet placed on the table. They follow the sheet at a certain height by providing arc voltage control during cutting.

What is Plasma Cutting Machine?

Plasma cutter is an effective way to cut thin and thick materials. Plasma cutting can be used in hobby shops as well as wide-scale mass production. Plasma cutting is often used for a variety of industries. These industries include, automotive sector, construction sector as well as other types of manufacturing. Plasma cutting machines cut through conductive materials by using hot plasma. Typically, steel, stainless steel, aluminum and copper materials are used with plasma cutting. Other conductive metals can be cut also.

Leave a message online

If you are interested in our company's products, please fill in the relevant information on this page and submit. A staff member will contact you in time, or please call us directly.