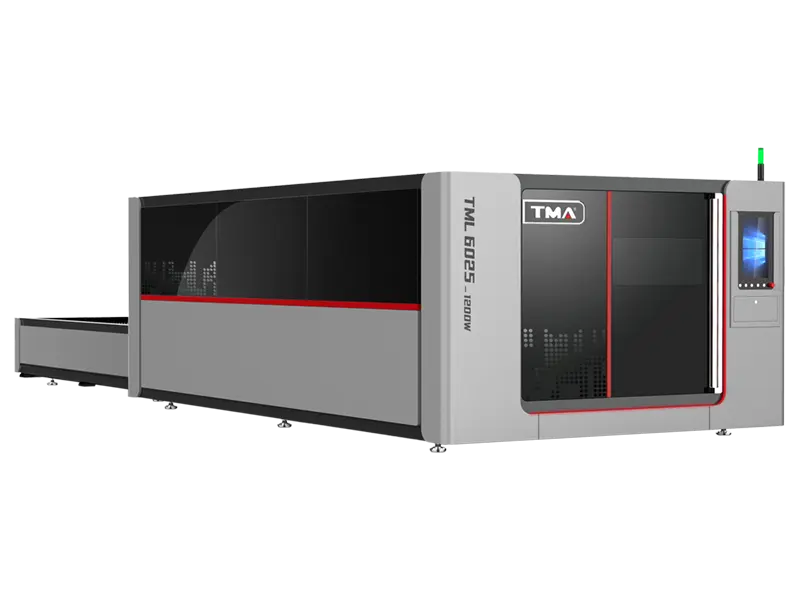

Press Brake

Electricl CNC

The full electrical servo bending machine is a advanced metal plate processing equipment combined with electrical servo technology and CNC technology.

Introduction to Configuration

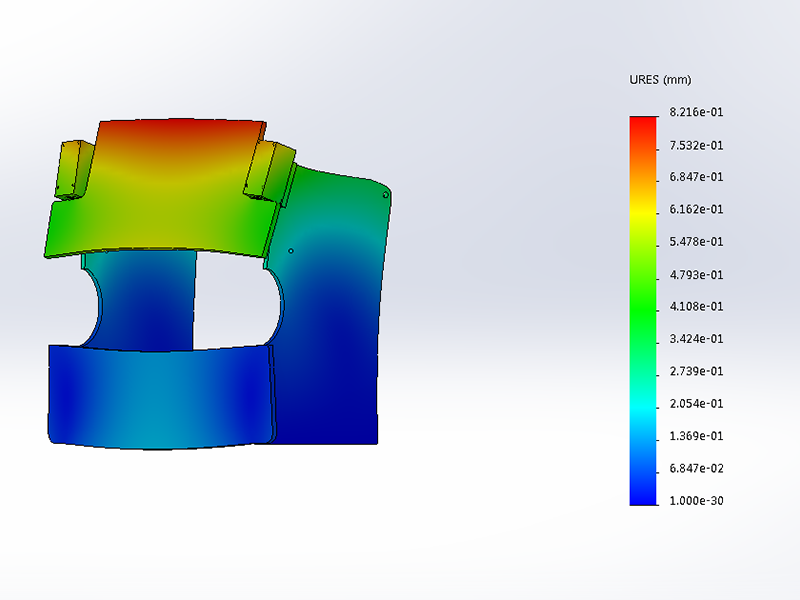

Superior Technology Creates Excellent Quality

With the help of advanced digital design platforms, our engineers use three -dimensional construction simulation technology and Solidworks 3D CAD to accurately draw the three -dimensional model of machines, and perform virtual assembly and performance simulation. This ensures a comprehensive prediction and optimization of equipment performance before real manufacturing.

Controller

We choose a series of control systems of internationally renowned brands, which are specially created for high -end bending machines to meet the high standard requirements of customers.

These control systems adopt top CNC technology and intelligent algorithms to ensure that bending processing is accurate and correct, and its stability and reliability are excellent.

They have powerful functions, flexible operations, support multiple modes, and easily meet different processing needs. At the same time, the humanized interface design makes the operation more convenient.

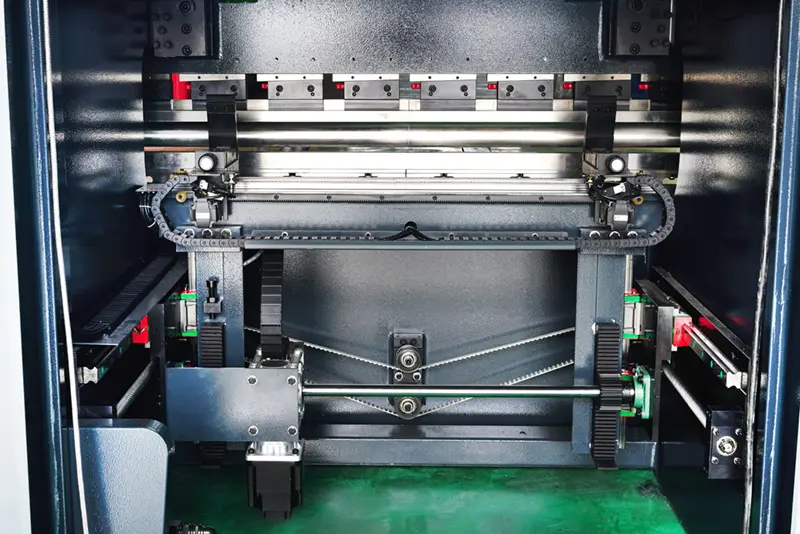

Backgauge

After the CNC press brake, the material is based on its high -level intelligent design, providing unprecedented accuracy and efficiency guarantee for metal plate bending.

It adopts advanced CNC technology. Through accurate computing and automatic adjustment, the precise control of the post -material block position can be achieved to ensure that each bend can achieve extremely high accuracy and repetitiveness.

At the same time, the rear block also has an intelligent avoidance function, effectively preventing the processing of processing parts from colliding with it, and improving the safety and stability of the entire processing process.

Electrics:

The German Rexroth fully closed-loop electro-hydraulic servo high-frequency synchronous control system is adopted to ensure that the machine tool has high stability and high precision in the process of high-speed operation.

Advantage:

The frequency response (response frequency) is higher

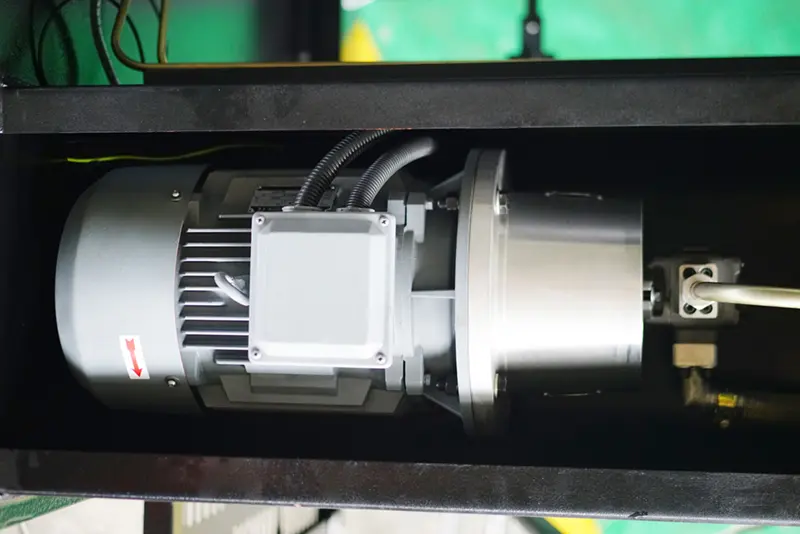

Motor

The famous brand motor increases the service life of the machine and keeps the machine working in a low-noise environment.

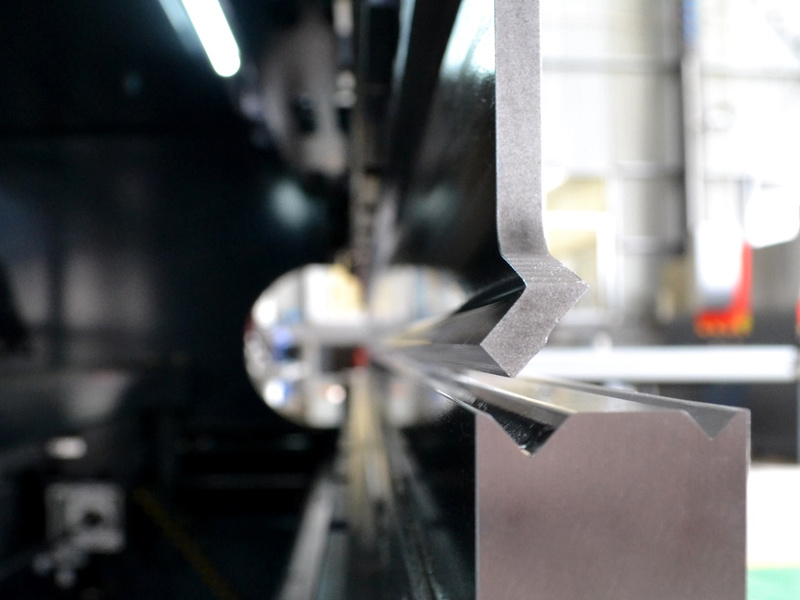

Punches & Dies

Sheet Metal Press Brake punches and dies will be one of the most important topics we discuss before you place the order. Any bending shape will be completed by a suitable set of punch and die. We can provide appropriate toolings according to different bending requirements of customers.

Electric Crowning (Optional)

◐ Very precise bending angles

◐ Europe type dies with 60 mm and 90 mm

◐ Base can be clamped as well as single dies with 13 mm tang

◐ Electric crowning with a controller

◐ Precise positioning and alignment of the crowning table

◐ Easy and fast usage

Italy DSP Laser Protection (Optional)

DSP® laser protection will be necessary if you have a high requirement for the safety.

Advantage:

Laser protection, Multi beam Receiver

Pretective areas, Front, center and rear

The safety level is CAT.4 and SIL3

Detection Case protection degree: IP 65

Laser classification: class 1 M

Response time: 5 ms

Change Speed Point : 5mm + Stopping Space

The maximum protective distance is up to 15M

LED indicators show various states

Standard Equipment

REQUEST INFORMATIONHigh Efficiency Motor - Class IE3

Oil Pump: Sunny - USA

Electrics: Schneider Electric - France

Sealing Ring: PARKER - America

Main Motor: Siemens Motor - Germany

High Efficiency Motor - Class IE3

Servo Motor: ESTUN

Tube Connector: EMB - Germany

Foot Switch: KACON - South Korea

Backgauge: Hiwin - Taiwan

Hydraulic System: Bosch Rexroth - Germany

Grating Ruler: Fagor

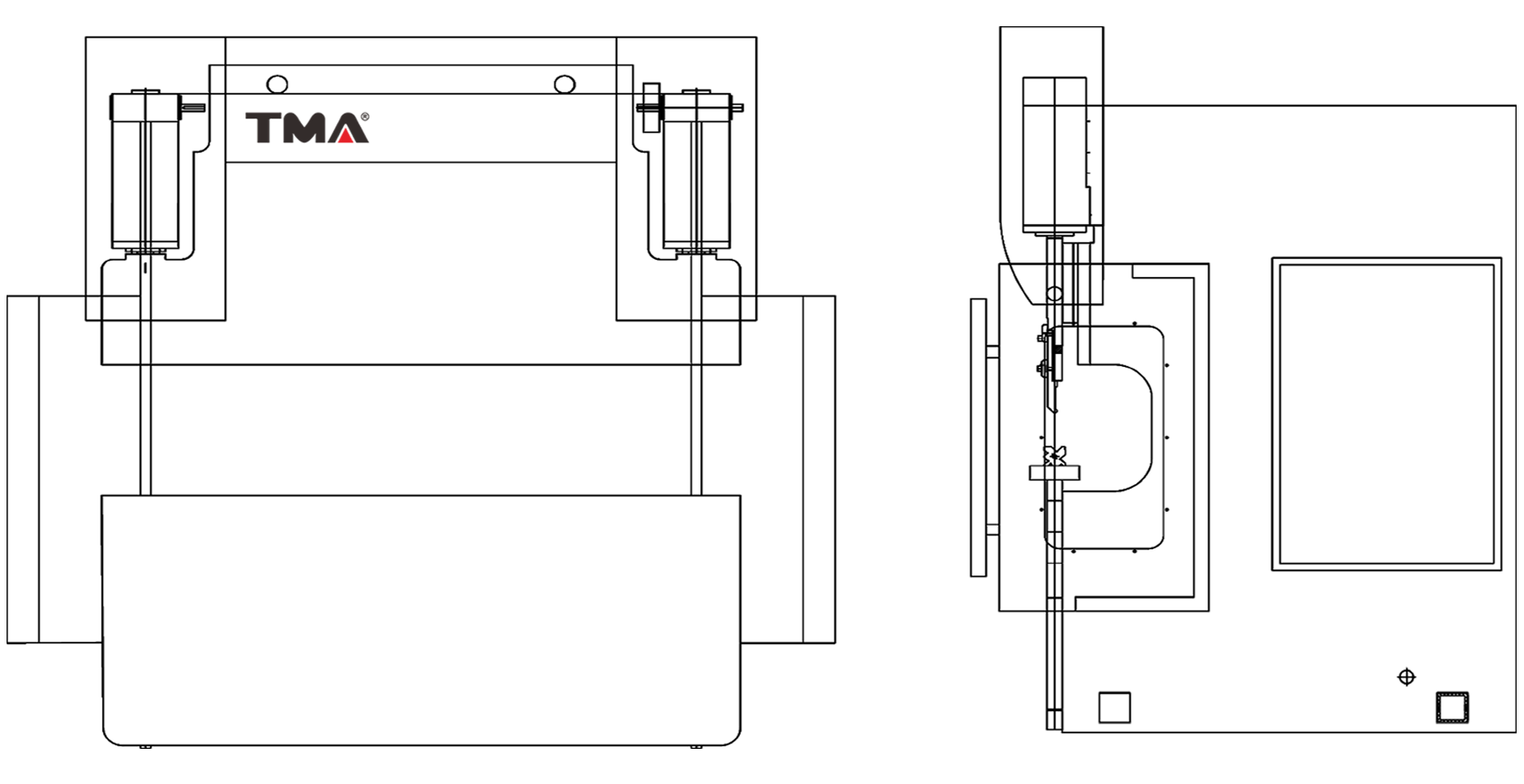

Technical Parameter

| Model | Unit | E40T/1600 | E50T/2000 |

| Nominal pressure | KN | 400 | 500 |

| (A) Bending length | mm | 1600 | 2000 |

| (B) Column spacing | mm | 1380 | 1700 |

| (C) Throat Depth | mm | 300 | 350 |

| (D) Cylinder stroke | mm | 100 | 180 |

| (E) Maximum opening height | mm | 420 | 420 |

| (F) Mold height | mm | 470 | 470 |

| X axis moving speed | mm/s | 600 | 600 |

| Drive speed | mm/s | 200 | 200 |

| Compression speed | mm/s | 17 | 17 |

| Retum speed | mm/s | 180 | 180 |

| Machine axis | axis | 6 Axis, no Crowning | 6 Axis, no Crowning |

| X-axis stroke | mm | 500 | 500 |

| R-axis stroke | mm | 150 | 150 |

| Main motor power | KW | 2*5.5 | 2*7.5 |

| Power capacity | KVA | 29 | 35 |

| Weight | Kg | 4000 | 5000 |

| Machine dimensions | mm | 1960/1600/2500 | 2500/1650/2500 |

Product Video

Electrical CNC

Related Products

Service Advantage

Excellent Processing Equipment

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a two-year warranty and a one-stop service for lifetime maintenance.

Tailor-made Solutions

According to your needs and circumstances, reasonable complete equipment solutions and knowledge training can be customized for you.

Super Cost-effective

The company has excellent production environment conditions, complete production process equipment, mature production and manufacturing system, and rich production and manufacturing experience.

Perfect After-sales System

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Qualification

Leave a message online

If you are interested in our company's products, please fill in the relevant information on this page and submit. A staff member will contact you in time, or please call us directly.