Hydraulic Press

YW41 Series Single Column Hydraulic Press

CNC Hydraulic Press Series , perfectly equipped for sensitive bending, energy efficient solutions. With its easy to use control units, rigid body frame, perfect design, high efficiency, multiple tool usage solutions, top level CE safety standards and with its suitable price range, CNC Hydraulic Press is the World leader in its category. Perfectly equipped for sensitive bending, energy efficient solutions.

Introduction to Configuration

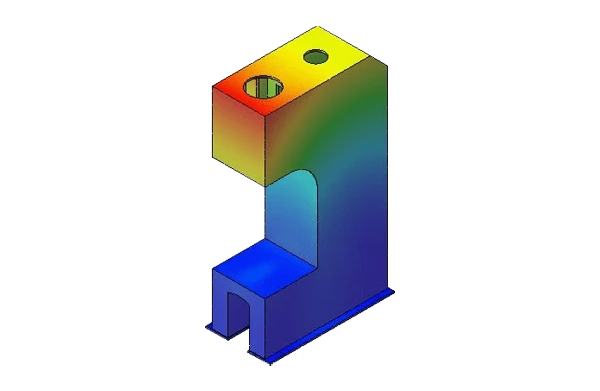

FEA & Stress Analysis

Stress Analysis & Finite Element Analysis

The CAE software SOLIDWORKS used as the method to analyze the linear static construction, stress and deformation for press break and laser cutting machine frames. So for complicated structures, highly complex loading’s, transient modelling and combination of the above, FEA makes sense.

STRUCTURE AND TABLES

YW41-series C-frame presses consist of an electro welded structure made solely of S355JR steel. They are stabilised and machined at the end of the structural welding process to ensure perfect parallelism and precision. Calculated and designed by finite. With all this, we always guarantee our high precision and quality standards. These models are equipped with a mechanized lower and upper C45E steel table with DIN-650 grooves. The upper table ensures perfect alignment by means of two cylindrical lateral guides of 50 mm diameter with maintenance free anti-friction bimetallic caps.

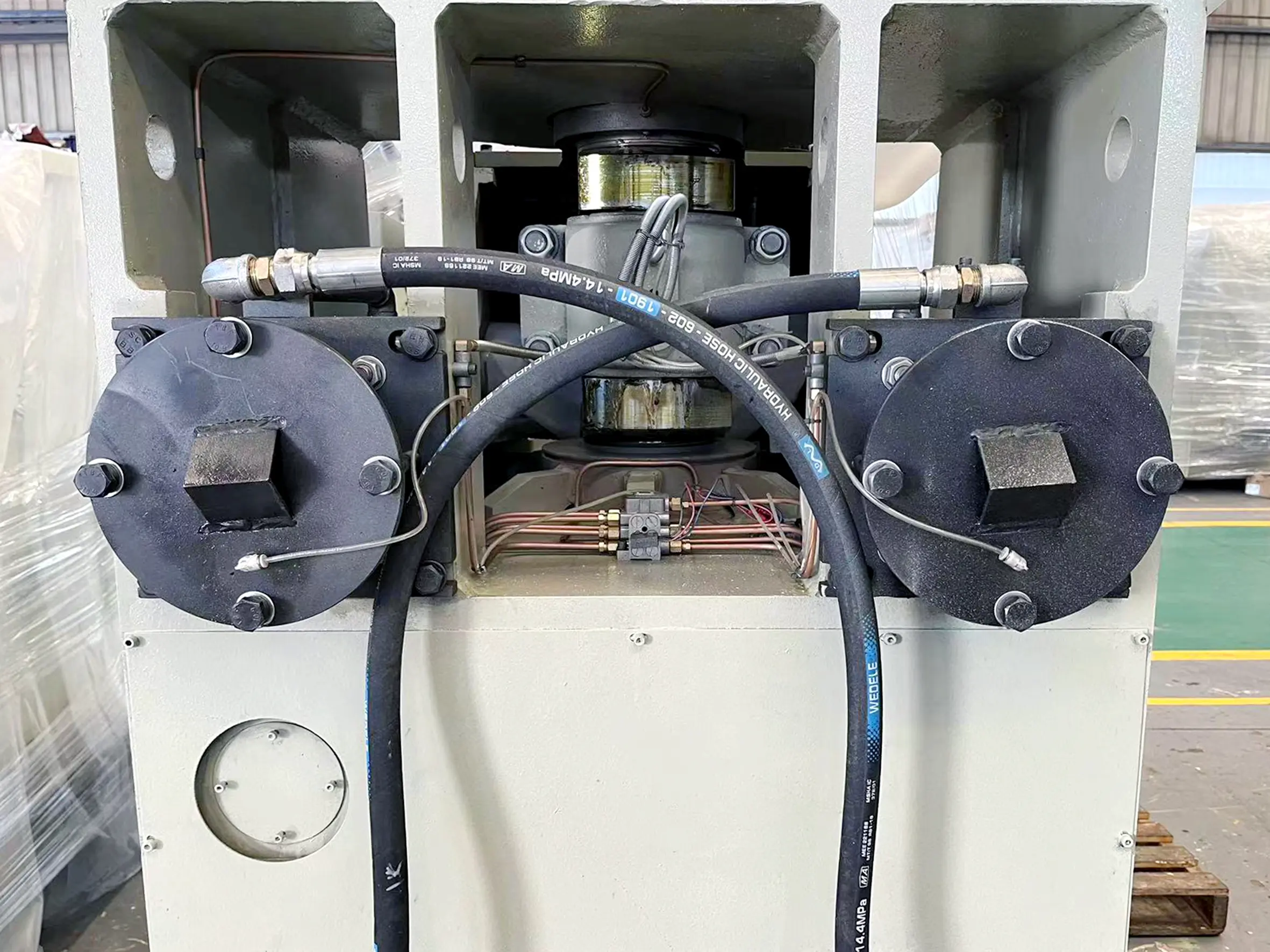

CYLINDER AND HYDRAULIC UNIT

The cylinder is double acting with a chrome plunger and maintenance-free anti wear guides. Anti-turning of the cylinder with a squared front ant stroke endings come as standard which enable us to conveniently regulate the cylinder stroke.

A two-speed motorized hydraulic unit with automatic high speed deactivation. It’s equipped with a cylinder decompression valve. A pressure switch placed at the lateral part comes as standard which allows the regulation of the most appropriate pressure signal for each kind of pressing.

They are supplied with a glycerin gauge with reading in tonnes.

ELECTRIC INSTALLATION AND SAFETY

The control panel features a switch enabling the user to select the desired type of work in a manual, semi-automatic or automatic position and a switch to select either the fast speed or slow speed. Electrical and hydraulic manoeuvres are redundant and self-controlled. They incorporate an additional safety block and self-control devices for manoeuvre and safety. It includes the verification and certification of the correct operation and the safety distance for the photocells.

Operation is carried out by low voltage electric pedals.

Safety is guaranteed by the use of two lateral protections and with level IV safety light curtains situated at the front.

They allow the installation of a hydraulic cushion or a hydraulic ejector. They are supplied with an instructions manual.

It meets and satisfies all the essential health and safety requirements in accordance with the EC standard.

Standard Equipment

REQUEST INFORMATIONStandard Equipment

Mitsubishi - Japa

Main Motor: Siemens Motor - Germany

Foot Switch: KACON - South Korea

Sealing Ring: PARKER - America

Electrics: Schneider Electric - France

Foot Switch: KACON - South Korea

Oil Pump: Sunny - USA

High Efficiency Motor - Class IE3

Technical Parameter

| Specifications | Unit | YW41-10C | YW41-25C | YW41-40C | YW41-63C | YW41-63 | YW41-100C | YW41-160 | YW41-200 | YW41-315 | YW41-400 | YW41-500 | ||

| Nominal | kN | 100 | 250 | 400 | 630 | 630 | 1000 | 1600 | 2000 | 3150 | 4000 | 5000 | ||

| Opening Height | Correcting | mm | / | / | 600 | 550 | / | 600 | 700 | / | / | / | / | |

| Pressing | mm | 630 | 630 | 770 | 800 | 800 | 900 | 1000 | 1200 | 1200 | 1200 | 1500 | ||

| Stroke Of Slide | mm | 400 | 500 | 500 | 500 | 500 | 500 | 500 | 710 | 800 | 800 | 900 | ||

| Throat Depth | mm | 250 | 290 | 325 | 350 | 350 | 350 | 350 | 360 | 380 | 450 | 800 | ||

| Shank Hole | mm | 140 | 180 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | ||

| Slide Speed | Ldle Down | mm/s | 80 | 50 | 40 | 50 | 50 | 34 | 27 | 90 | 100 | 100 | 100 | |

| Return | mm/s | 160 | 110 | 80 | 100 | 100 | 75 | 70 | 60 | 65 | 65 | 70 | ||

| Bolster | L-R | Correcting | mm | / | / | 1000 | 1600 | / | 2000 | 2000 | / | / | / | / |

| Pressing | mm | 410 | 510 | 600 | 630 | 650 | 700 | 750 | 1400 | 1800 | 1800 | 2000 | ||

| F-B | mm | 420 | 570 | 550 | 600 | 600 | 600 | 600 | 800 | 1200 | 1300 | 1400 | ||

| Between Bolster & Floor | Correcting | mm | / | / | 770 | 850 | / | 1000 | 1000 | / | / | / | / | |

| Pressing | mm | 710 | 710 | 600 | 600 | 730 | 700 | 700/630 | 900 | 1200 | 1400 | 1400 | ||

| Motor Power | Kw | 2.2 | 4 | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 15 | 22 | 22 | 37 | ||

Product Video

Related Products

Service Advantage

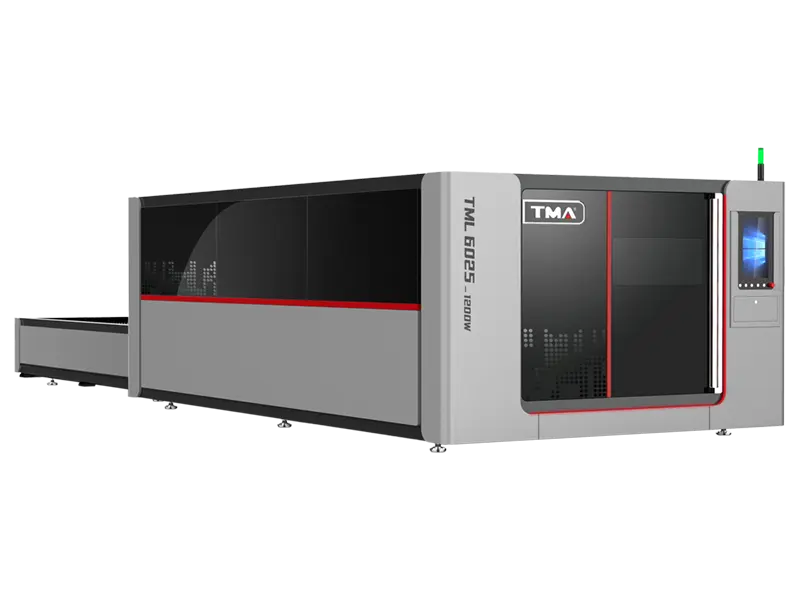

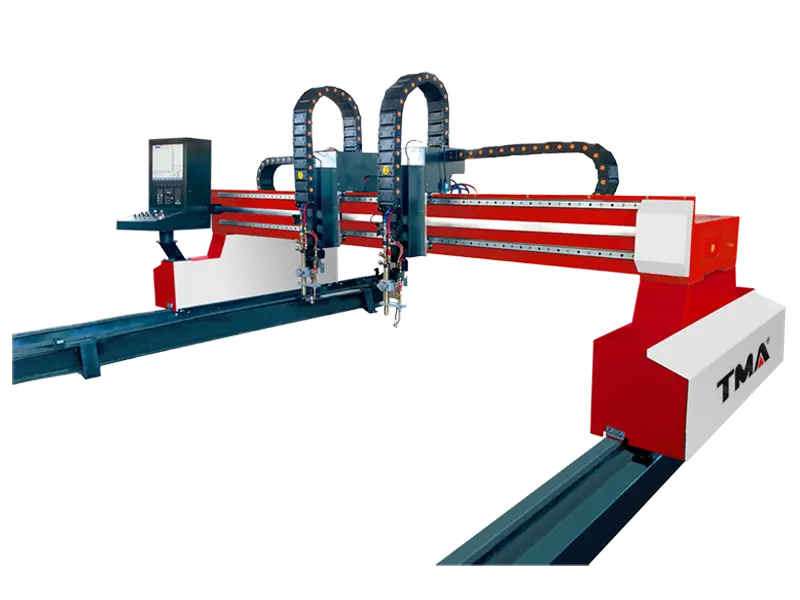

Excellent Processing Equipment

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Tailor-made Solutions

According to your needs and circumstances, reasonable complete equipment solutions and knowledge training can be customized for you.

Super Cost-effective

The company has excellent production environment conditions, complete production process equipment, mature production and manufacturing system, and rich production and manufacturing experience.

Perfect After-sales System

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Qualification

Leave a message online

If you are interested in our company's products, please fill in the relevant information on this page and submit. A staff member will contact you in time, or please call us directly.