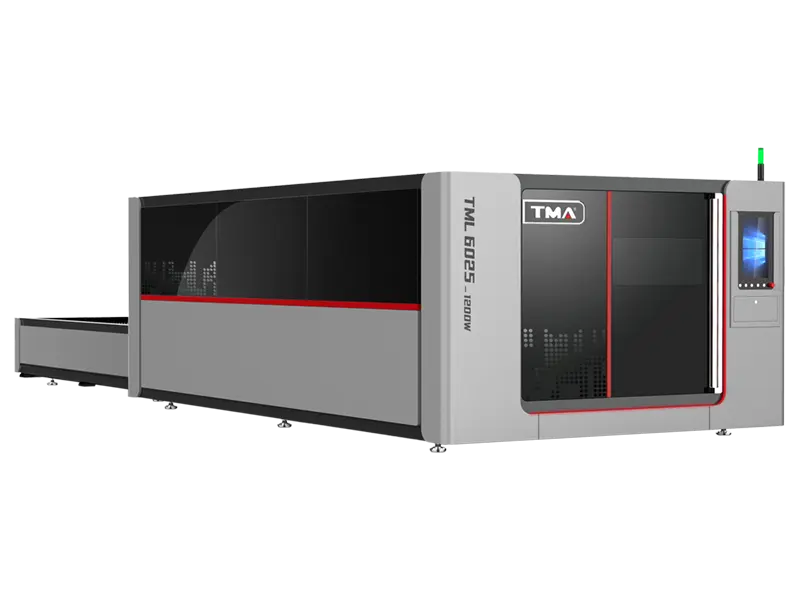

Laser Cutting Machine

High Configuration Series Fiber Laser Cutting Machine

TMA Machine top rated fiber laser cutting machine is designed for metal fabrication, including steel, aluminum, titanium, alloy, brass, copper, and iron, with different laser powers(1000W, 1500W, 2000W, 3000W, 4000W, 6000W, 8000W, 12000W, 20000W). The affordable fiber laser cutter is for sale at a low price, with the best fiber laser cutting system service and support.

Introduction to Configuration

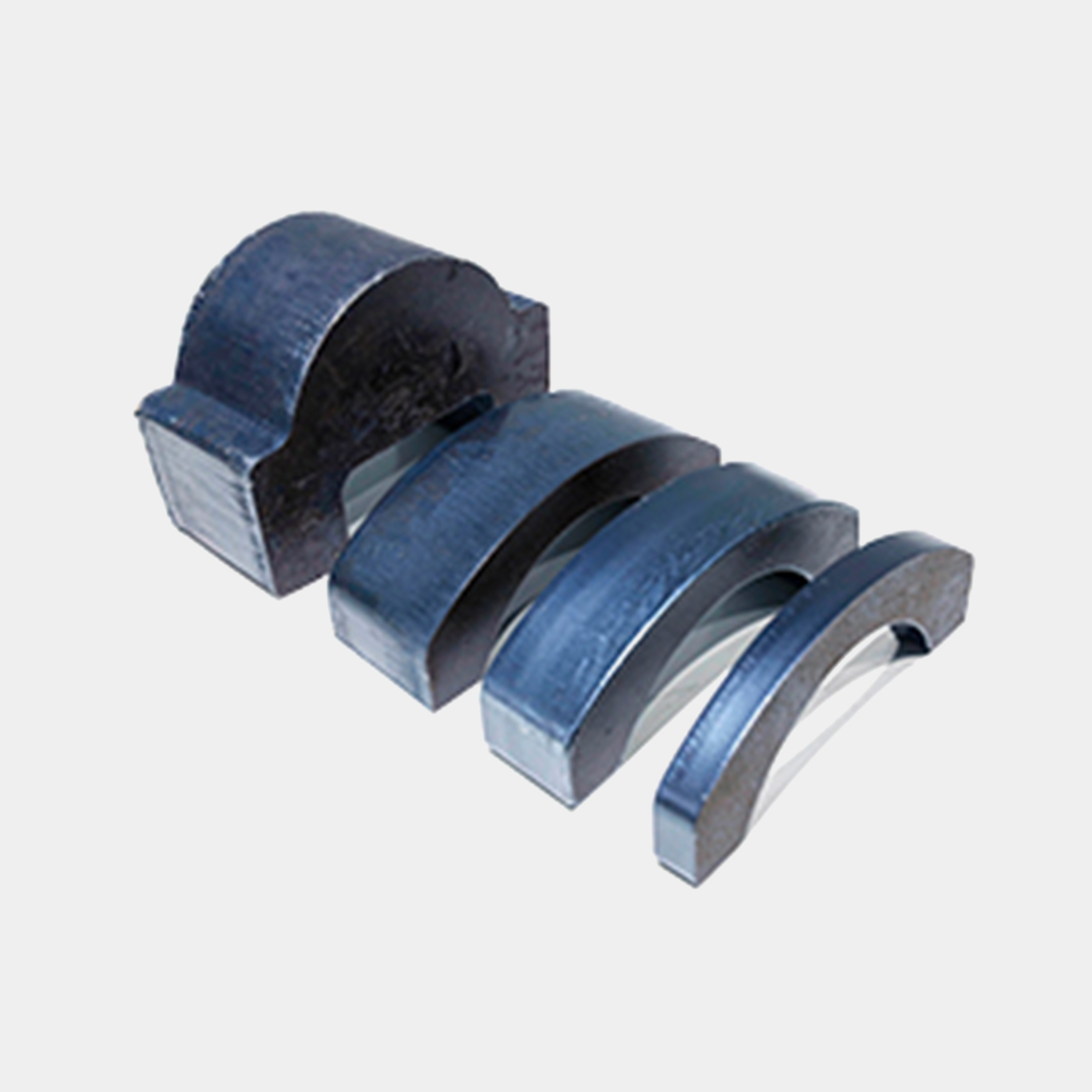

Super heavy Steel Welding Machine Bed

The laser cutter machine’s bed adopts 12mm super-thick monolithic steel plate laser blanking. The groove welding method makes the plates reach equal strength butt. Then it undergoes stress annealing and natural aging treatment to eliminate internal stress and maintain the bed’s extremely high stability and cutting accuracy.

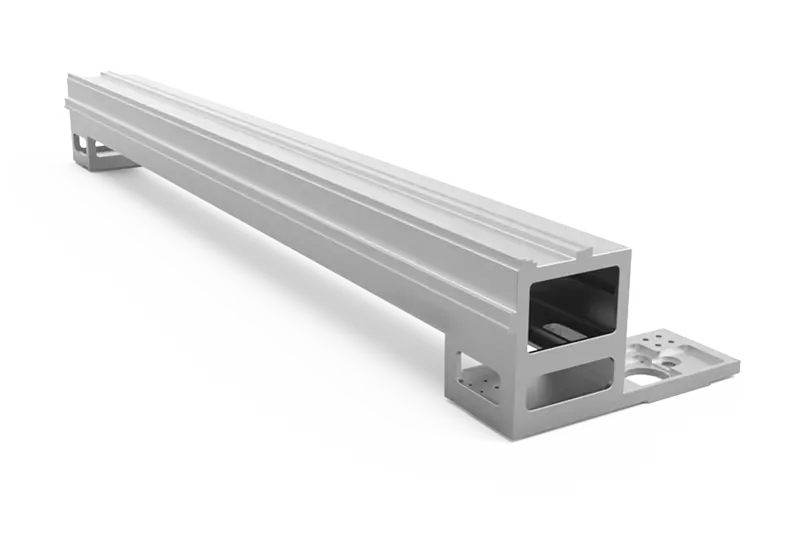

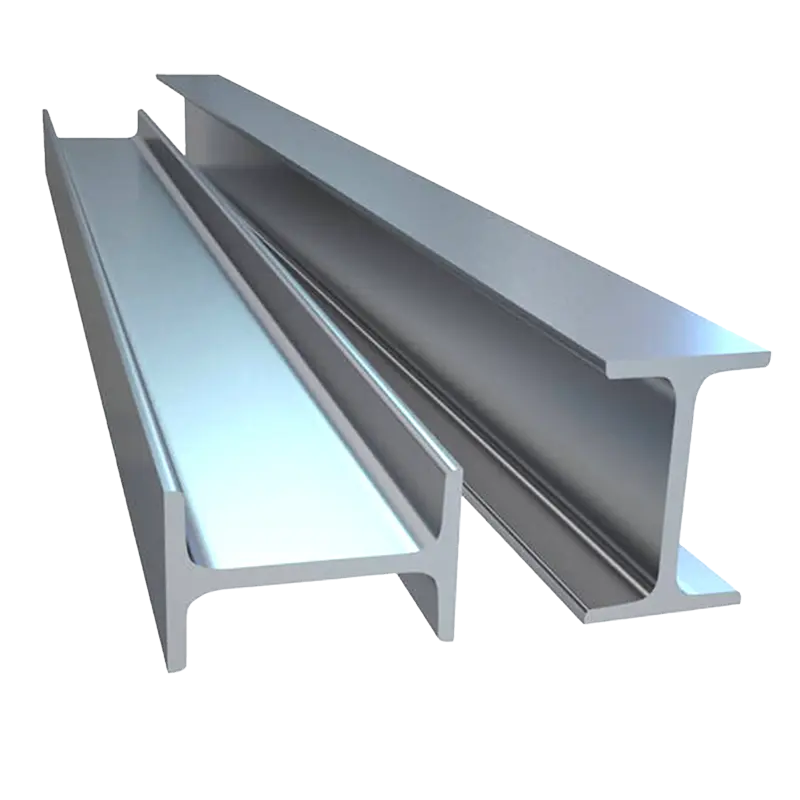

The Fifth-generation Aviation Aluminum Alloy Beam

The T6 heat treatment process processes the laser cutter machine’s full beam to make the shaft obtain the highest strength. Solution treatment improves the strength and plasticity of the beam, optimizes and reduces its weight, and speeds up the movement.

Intelligent Control System

“CypCut plane cutting” software is a set of software specially developed for the deep customization of the laser cutter machine industry. Easy to use, rich in functions, and suitable for various processing occasions.

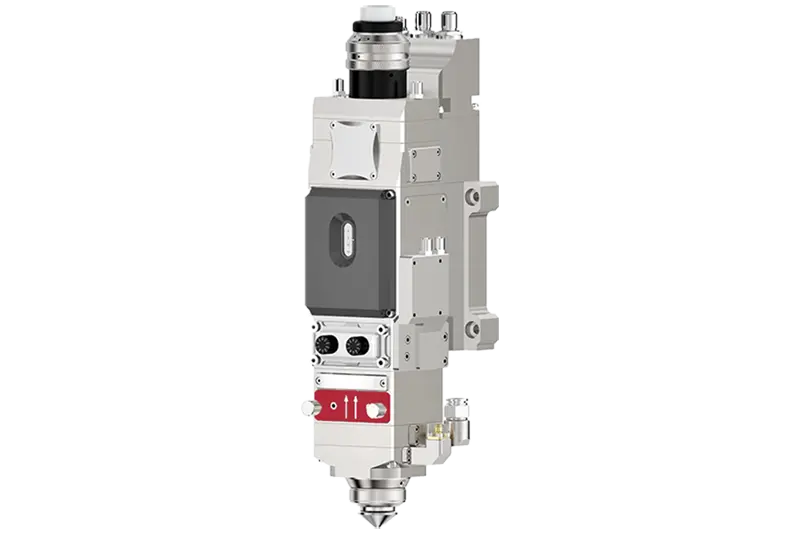

Auto focusing laser head

The laser cutter machine’s auto-focusing optical fiber cutting head has a built-in motor drive unit. A linear mechanism automatically drives the focus lens to change the position within the specified range. The program can set the continuous focus to complete the rapid perforation of thick plates and automatically cut plates of different thicknesses and materials.

Servo Motor:

We can install this small laser cutter machine in a 20GP container to protect the fuselage from damage during transportation, reduce transportation costs, and facilitate loading and unloading. Portation, reduce transportation costs and facilitate loading and unloading.

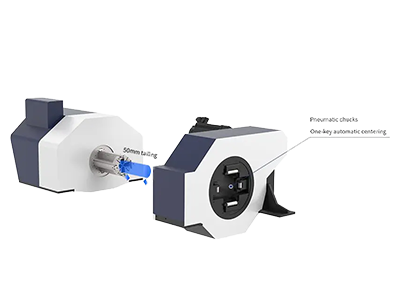

Double Pneumatic Chucks, Ultra-short Tailing

The front and rear of laser cutting machine chucks are featured by automatic centering and dual-driven rotation, keeping them synchronous. The front chuck is full-stroke, and cutting tailing is further shortened to 50mm by front chuck avoidance cutting.

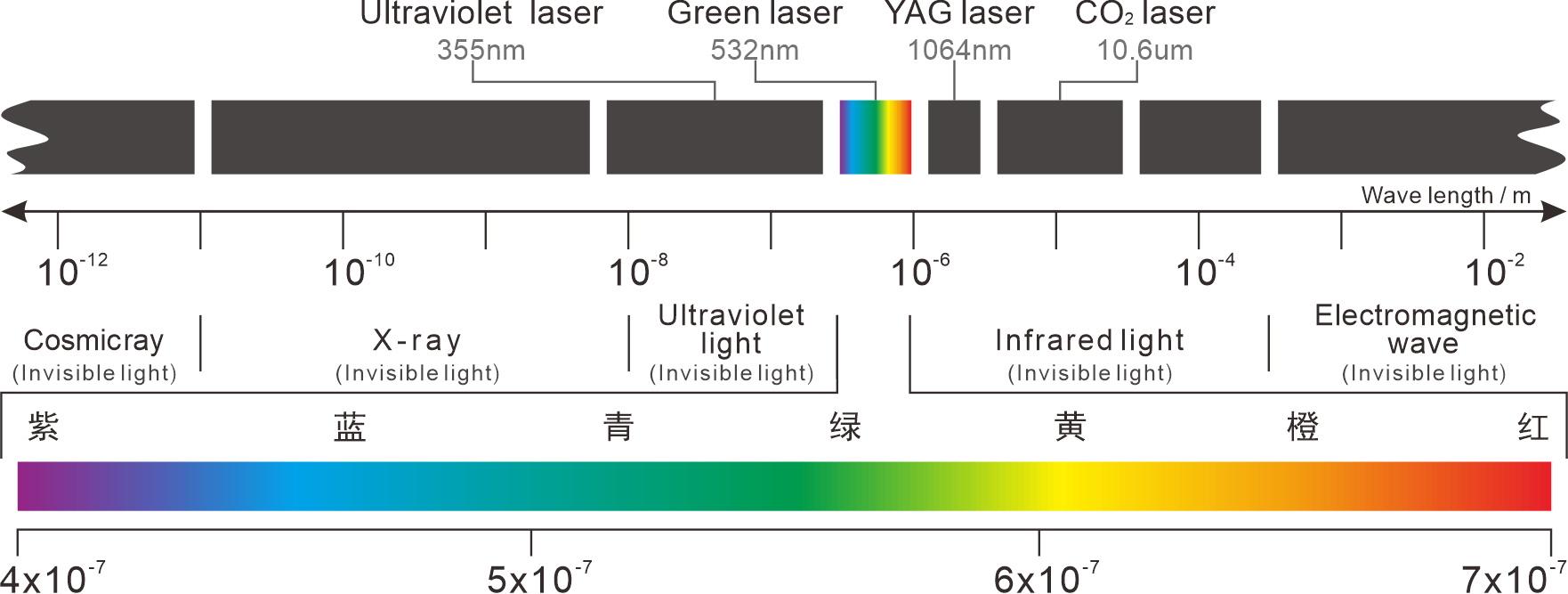

Application Materials of laser cutting machine

TML-6000 sheet metal laser cutting machine can cut carbon steel, stainless steel, aluminum alloy, galvanized sheet, titanium alloy, manganese alloy, Etc. The device is widely used in metal tube processing, auto parts manufacturing, electrical manufacturing, elevator manufacturing, petroleum machinery, food machinery, and decorative advertisements.

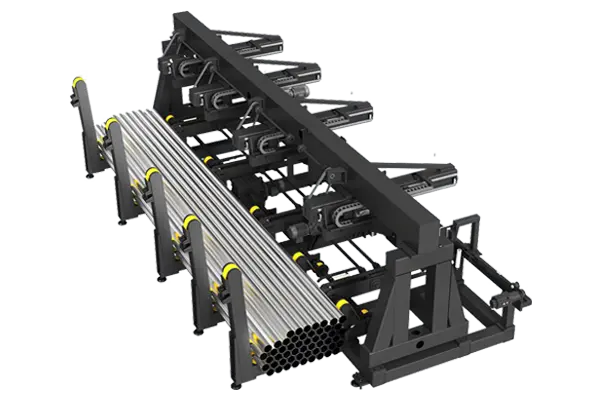

Automatic Loading Equipment(Optional)

◐ Tubes are usually loaded to material laying area by transmission mechanism of which limiting device can make tubes in order.

◐ Tubes are clamped by 6 loading rollers that need no reset in a loading cycle, resulting in less waiting time and high cutting efficiency.

Standard Equipment

REQUEST INFORMATIONIPG Fiber Laser Welding - Germany

MAX Fiber Laser Welding - China

Raycus Fiber Laser Welding - China

Technical Parameter

| TYPE | 3015 | 4015 | 4020 | 6015 | 6020 | 6025 | 8025 |

| Processing Gange | 3000mm*1500mm | 4000mm*1500mm | 4000mm*2000mm | 6000mm*1500mm | 6000mm*2000mm | 6000mm*2500mm | 8000mm*2500mm |

| Laser Power | 1500W / 3000W / 6000W / 12000W / 24000W / 30000W | ||||||

| X-Axis Travel | 1525 | 1525 | 2025 | 1525 | 2025 | 2525 | 2525 |

| Y-Axis Travel | 3025 | 4025 | 4025 | 6025 | 6025 | 6025 | 8025 |

| Z-Axis Travel | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Positioning Accuracy | ±0.05mm/m | ||||||

| Repeated Positioning Accuracy | ±0.03mm/m | ||||||

| Maximum Linkage Speed | 100m/min | ||||||

| Maximum Acceleration | 1.5G | ||||||

Product Video

Single Worktable

Related Products

Service Advantage

Excellent Processing Equipment

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Tailor-made Solutions

According to your needs and circumstances, reasonable complete equipment solutions and knowledge training can be customized for you.

Super Cost-effective

The company has excellent production environment conditions, complete production process equipment, mature production and manufacturing system, and rich production and manufacturing experience.

Perfect After-sales System

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Qualification

Leave a message online

If you are interested in our company's products, please fill in the relevant information on this page and submit. A staff member will contact you in time, or please call us directly.