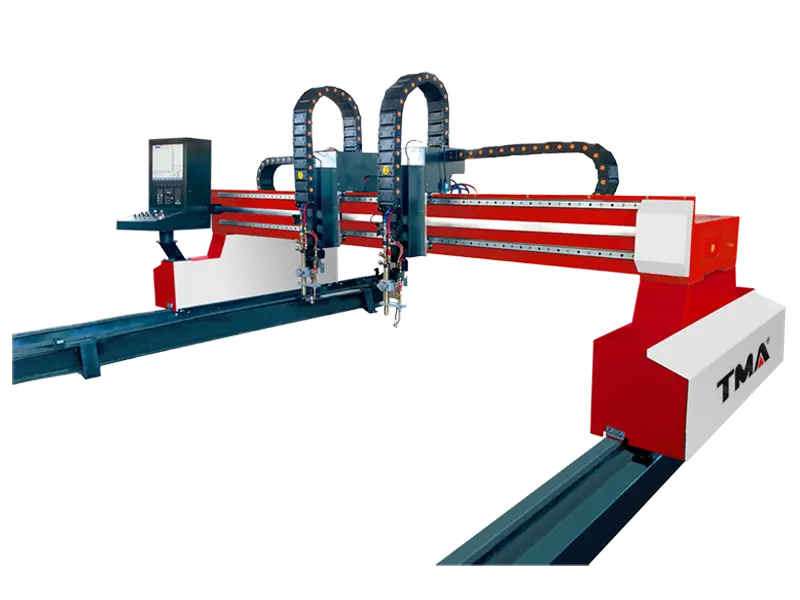

Iron Worker

Hydraulic Punching Machine

TMA Hydraulic Punching machines ranging from 35 to 200 tons of punching capacities, combined with different throat depths to choose from, provides a complete range of models to meet our customer’s wide range of requirements.

Introduction to Configuration

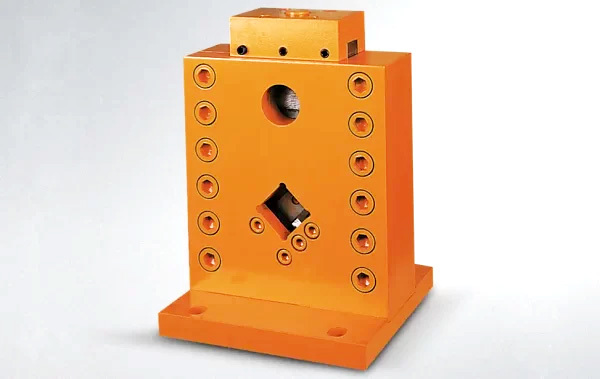

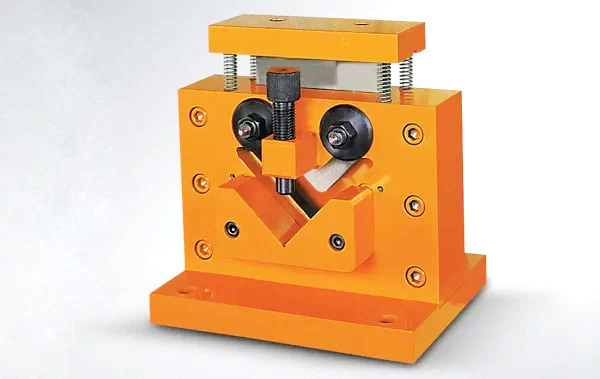

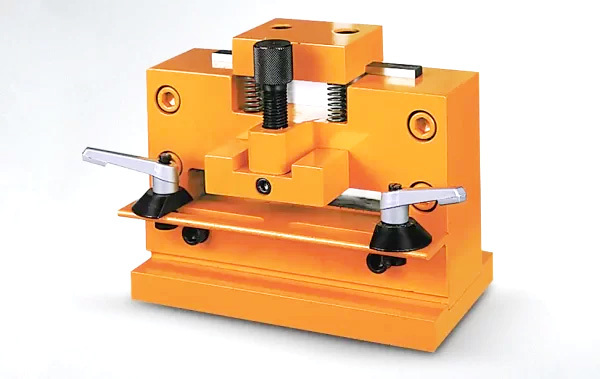

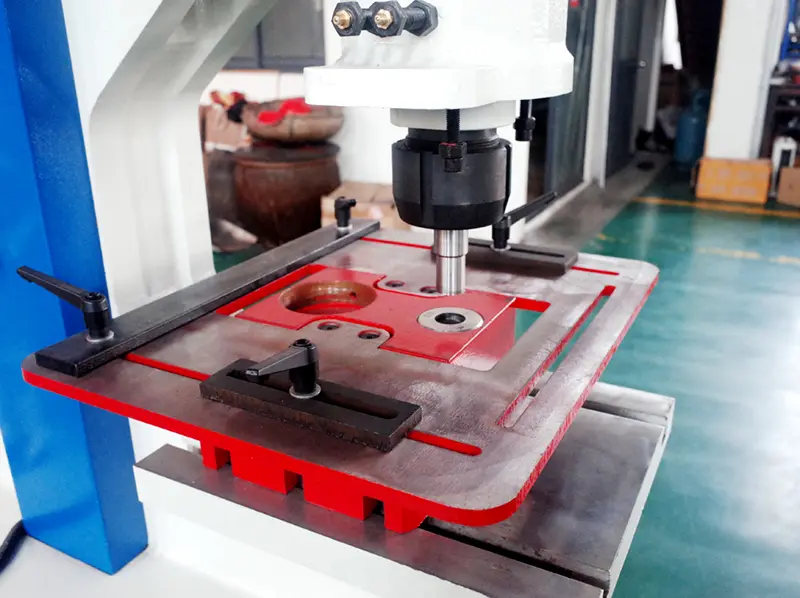

Punching Station

All metal punching operations of the ironworker machine are processed using hydraulic power, thus allowing the machine to punch very efficiently and silently. Punching is silent, powerful, and efficient. The device can either be used to hit thick metal or thin materials layered together. The waste materials come off together and in layers. The punching table consists of two parts: the first is the punching flange, and the second is the holder. There are different holders for different materials. The holder is a device that prevents the fabric from coming back with the punch after cutting.

Electrics:

The German Rexroth fully closed-loop electro-hydraulic servo high-frequency synchronous control system is adopted to ensure that the machine tool has high stability and high precision in the process of high-speed operation.

Advantage:

The frequency response (response frequency) is higher

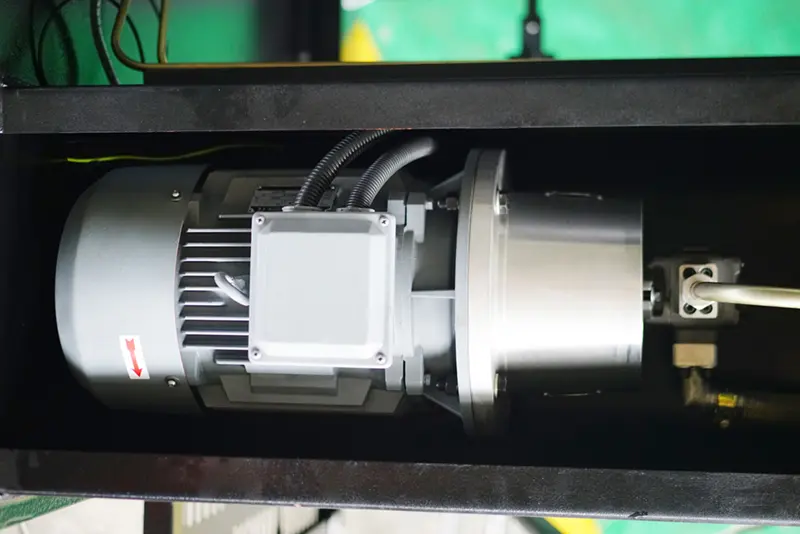

Motor

The famous brand motor increases the service life of the machine and keeps the machine working in a low-noise environment.

Standard Equipment

REQUEST INFORMATIONElectrics: Schneider Electric - France

Main Motor: Siemens Motor - Germany

Foot Switch: KACON - South Korea

Hydraulic System: Bosch Rexroth - Germany

Oil pump: First/Sunny - USA

Sealing Ring: PARKER - America

Technical Parameter

| Model | Unit | Q25YS-16 | Q25YS-20 | Q25YS-25 | Q25YS-30 | Q25YS-40 | Q25YS-50 |

| Pressure | T | 60 | 90 | 120 | 160 | 200 | 250 |

| Plate Strengtd | N/mm² | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 |

| Slider Stroke | mm | 80 | 80 | 90 | 100 | 110 | 200 |

| Punching Stroke Times | T/min | 10-20 | 12-22 | 8-18 | 6-16 | 6-16 | 6-16 |

| Punching Plate tdickness | mm | 16 | 20 | 25 | 30 | 35 | 40 |

| Max Hole Diameter | mm | 25 | 30 | 35 | 38 | 40 | 45 |

| tdroat Deptd | mm | 300 | 335 | 480 | 600 | 535 | 600 |

| Main Motor | kw | 5.5 | 7.5 | 11 | 15 | 18.5 | 18.5 |

| Outline Dimension | mm | 1400X700X1700 | 1600X800X1800 | 1800X960X2000 | 2000X1050X2450 | 2200X1050X2450 | 2600X1440X2500 |

Product Video

Related Products

Service Advantage

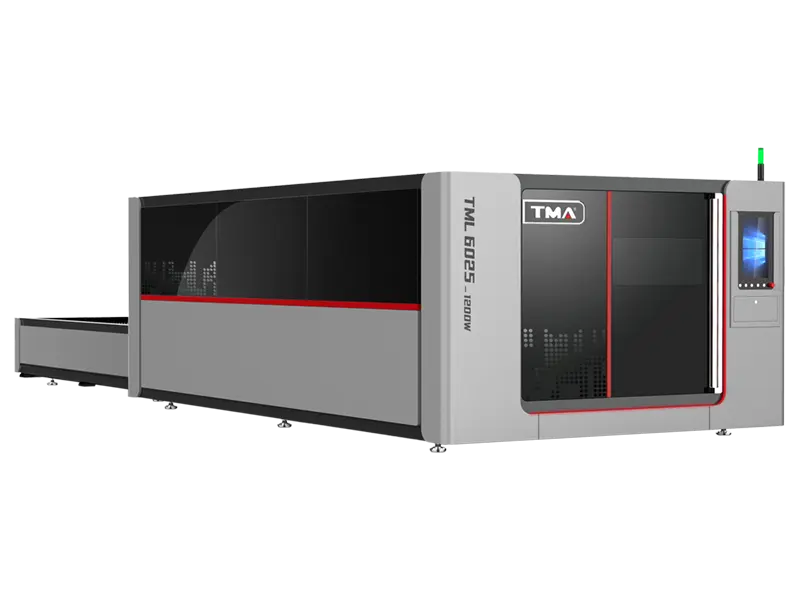

Excellent Processing Equipment

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Tailor-made Solutions

According to your needs and circumstances, reasonable complete equipment solutions and knowledge training can be customized for you.

Super Cost-effective

The company has excellent production environment conditions, complete production process equipment, mature production and manufacturing system, and rich production and manufacturing experience.

Perfect After-sales System

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Qualification

Leave a message online

If you are interested in our company's products, please fill in the relevant information on this page and submit. A staff member will contact you in time, or please call us directly.