Rolling Machine

TMA is the leading manufacturer of Plate Bending machines in China: a strong brand, a leader in technical innovation and customer service, with a global footprint. Today TMA is able to satisfy any type of request for the design and production of a Plate Rolling Machine and Plate Bending Machine: useful width from 200 mm up to 8000 mm and thickness from 0,5 up to 300 mm. We offer a complete selection of metalworking equipment, 2, 3, and 4 rollers bending machines, profile bending technology, straightening machines for convex bottoms, and finally, digital CNC systems with customized software.

What is Plate Rolling Machine?

The plate rolling machine is a kind of equipment that uses work rolls to bend sheet metal. It can form parts of different shapes, cylindrical and tapered. It is essential processing equipment. The working principle of the plate bending machine is to move the work roll through the action of hydraulic pressure, mechanical force, and additional external parties to make the plate bend or bend into shape. According to the rotation, movement, and position changes of work rolls of different forms, the plate rolling machine can process parts such as the oval, arc, and cylindrical elements.

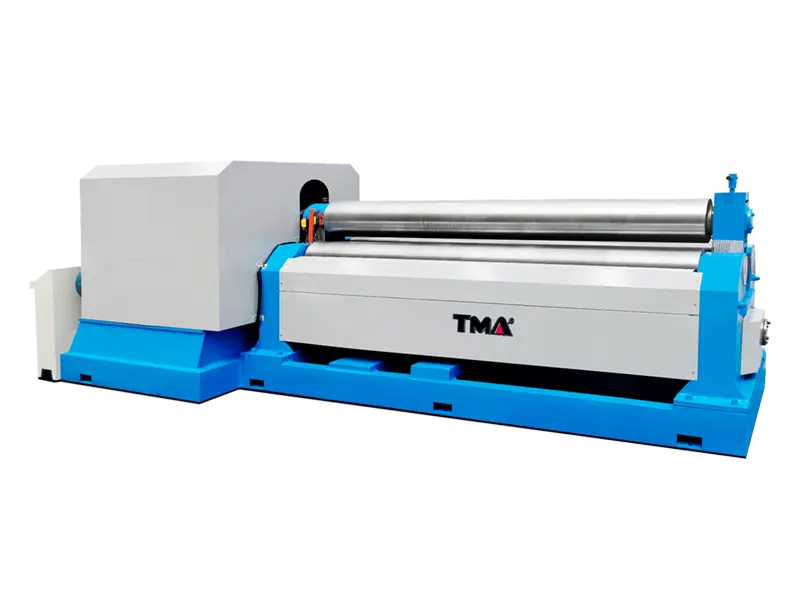

W11 Series Mechanical 3-Rollers Rolling Machine

The W11 Series plate roller machine is mighty and uses a pyramidal linear guide for bending rollers, which enables it to achieve the best bending results without guaranteed power loss. In the plate roller machine model W11, all three rollers use independent hydraulic gear motors directly coupled to the rolling roller shaft, which can ensure the superiority of torque and speed of these plate roller machines.

W11S 3-Rollers Variable Geometry Plate Roller Machine

The W11S plate rolling machine delivers multiple advantages to your fabrication infrastructure – a remarkably increased rolling capacity, reduced capital expenditure, and lower ongoing operational costs. They are the most attractive investment for heavy plate thickness (Above 80mm) applications.

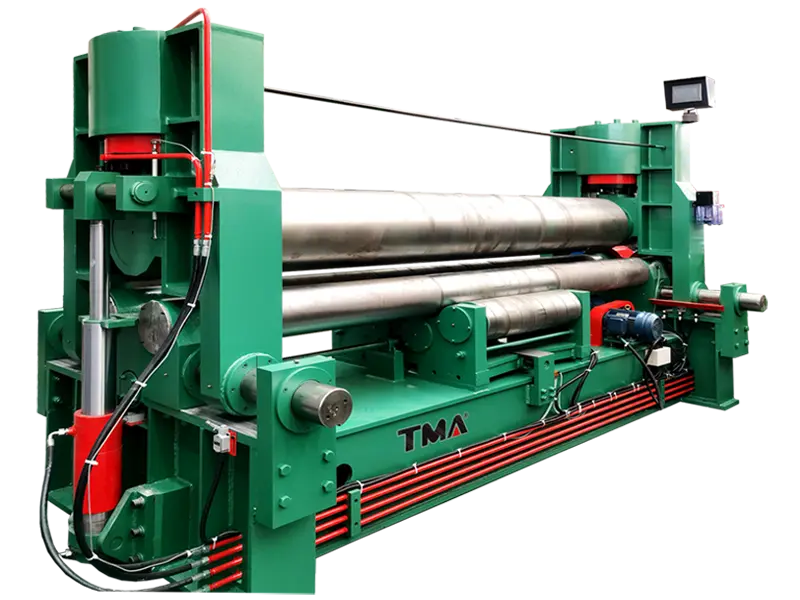

W12 4-Rolls Sheet Metal Plate Bending Machine

TMA CNC Four-Roller plate rolling machine, which is controlled by a CNC system to form a circle at one time, with a pre-bending and moving cone device, you can choose the coil support, and the coil support is left and right. It is the best choice for large coils with powerful functions, suitable for mass production, improved work efficiency, and saves labor.

W11F Asymmetric 3-Rollers Plate Bending Machine

W11F series plate bending machine adopts a strong electric welding structure, equipped with a super large steel roller. The side roller moves on a linear guide, bending the material near the tight point, thus ensuring that the device’s performance is comparable to that of the more expensive four-roller plate bending machine. In addition, the bending roll motion of the series three-roller plate bending machine ensures optimal traction. For asymmetric geometry and thin sheet, it can effectively prevent it from sliding during the pre-bending process.

Professional Profile Bending Machine

The WYQ24 series of corner rollers feature the guide roller following the main bending roller. Through the mechanical adjustment of the guide roller, support into the machine material, easy to roll Angle iron, and other asymmetric profiles. In the future, WYQ24 will ensure your position as a multi-faceted bending expert for key players. Operate your device with our Bluetooth bend control – custom-made for you.

FAQ

What is the working principle of W11 series plate rolling machine?

In the W11 series Symmetrical plate rolling machine, the upper roller of the W11 series Symmetrical scale rolling machine uses the hydraulic oil in the hydraulic cylinder to act on the piston to move vertically at the central symmetrical position of the two lower rollers. Provide torque for rolled sheets. The flat plastic metal plate of the bending machine passes between the three working rolls (two lower rolls and one upper roll) of the bending machine. With the help of the lower pressure of the upper roll and the rotation of the lower roll, the metal plate is passed through multiple passes. Continuous bending (the inner layer is compressed and deformed, the middle layer is unchanged, and the outer layer is stretched and deformed) to produce permanent plastic deformation and roll into the required cylinder, cone, or part of them. The disadvantage of this hydraulic three-roller bending machine is that the end of the plate needs to be pre-bent with the help of additional equipment. This rolling machine is suitable for large, more than 50mm thick devices. A row of fixed idlers is added under the two lower rollers to shorten the span of the two lower rollers, thereby improving the precision of the rolled workpiece and the machine’s overall performance.

What is the working principle of W12 series plate rolling machine?

The position of the upper roller of the W12 series plate bending machine is fixed, and the lower roller moves upward linearly to clamp the steel plate. The rollers on both sides transfer in a straight line or arc to move closer to the roller to adjust the radius of curvature of the reel. The four-roller and three-roller rolling machines have different roller motion forms, but the working principle is the same; they use the three-point fixed circle principle to carry out different radii moving. However, the pre-bending straight edge and roundness of the four-roller bending machine are better than those of the three-roller.

What are the types of rolling machines?

The type of plate bending machine varies depending on the field of use, from the transmission point of the mechanical type and hydraulic type. From the number of rolls, it is divided into three-roller and four-roller. The three-roller is divided into a symmetrical three-roller bending machine, asymmetrical three-roller bending machine, horizontal downward adjustment three-roller bending machine, W11S upper-roller universal bending machine, and four-roller CNC turning machine. In terms of the development of the plate bending machine, the upper-roller universal type is the most backward, and the four-roller CNC bending machine is the most advanced. Currently, the most commonly used in the market are the W11F partial Samsung plate bending machine, W11S upper-roller universal plate bending machine, W11 mechanical symmetrical plate bending machine, and W12 four-roller plate bending machine.

What are the performance and characteristics of the mechanical type plate rolling machine?

The mechanical type is divided into W11F asymmetrical plate rolling machine and W11 series symmetrical plate rolling machine.

Performance and characteristics of W11 series symmetrical plate rolling machine:

The structure of the machine is three-roller symmetrical type. The upper roller moves vertically at the symmetrical position of the two lower rollers. It is obtained by the transmission of the screw and screw nut. The two lower rollers rotate through the output gear of the reducer and the lower roller. The gears mesh to provide torque for the rolled sheet. The disadvantage of this machine is that the end of the plate needs to be pre-bent with other equipment.

Performance and characteristics of W11F asymmetrical plate rolling machine:

The structure of the machine is a three-roller asymmetrical type. The upper roller is the main drive, and the lower roller moves vertically to clamp the plate. The lower roller gear meshes with the upper roller gear and serves as the main drive at the same time; the side rollers are tilted and lifted. , With dual functions of pre-bending and rolling. Compact structure, convenient operation and maintenance.

What are the performance and characteristics of the hydraulic type plate rolling machine?

The hydraulic type is divided into W11S upper roll universal type and W12 four-roller plate bending machine:

The main features of W11S upper roll universal type: The upper roll universal bending machine adopts the upper roll lifting hydraulic drive and horizontal movement (mechanical transmission), driven by the lower roll, and the electric centralized

Leave a message online

If you are interested in our company's products, please fill in the relevant information on this page and submit. A staff member will contact you in time, or please call us directly.