Iron Worker

Hydraulic Iron Worker Machine

Q35Y Series Ironworkers allows two operators to use these ironworkers simultaneously in 5 workstations: Punching, Notching, Shearing Flat Bars, Angle Cutting, and Shearing Round and Square Bars.

Introduction to Configuration

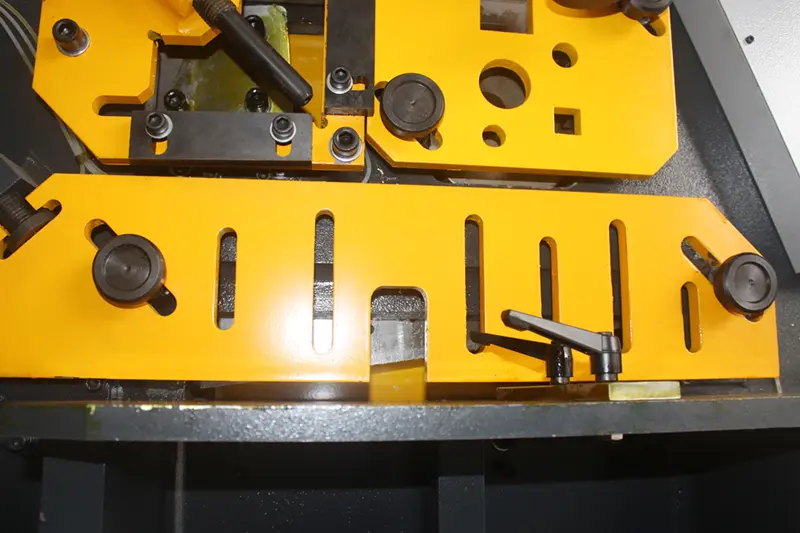

Punching Station

All metal punching operations of the ironworker machine are processed using hydraulic power, thus allowing the machine to punch very efficiently and silently. Punching is silent, powerful, and efficient. The device can either be used to hit thick metal or thin materials layered together. The waste materials come off together and in layers. The punching table consists of two parts: the first is the punching flange, and the second is the holder. There are different holders for different materials. The holder is a device that prevents the fabric from coming back with the punch after cutting.

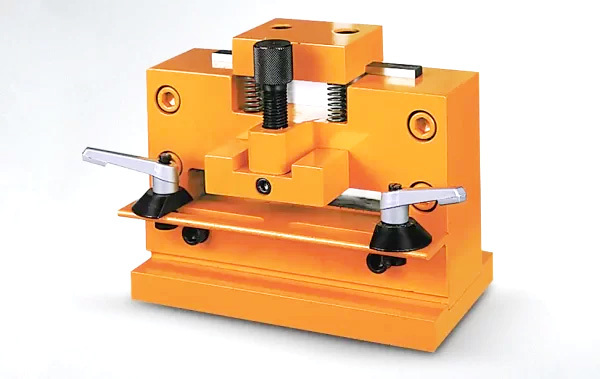

Flat Bars Shearing Station

The metal shear station of the ironworker machine has been equipped with simple and sturdy fixing mechanisms. Depending on the machine’s cutting capacity, You can adjust it for any steel thickness. The shearing capacity can go up to 17.71 inches in the flat bar or the cutting of corner profiles. The shearing blades, built for mass production, can be used on both sides (the upper blade has two cutting edges, and the lower blade has four cutting edges); this ensures a clean cut with minimal warping, from the total capacity to a thickness of only 1/8 inch.

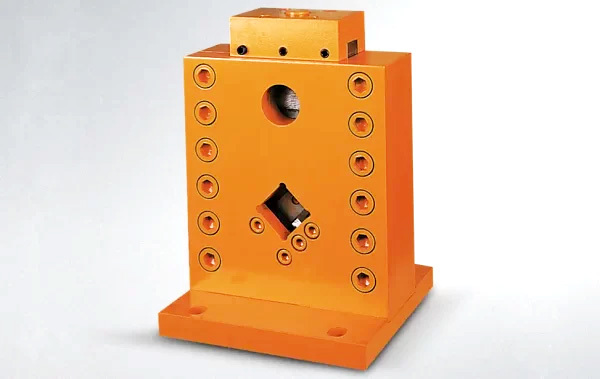

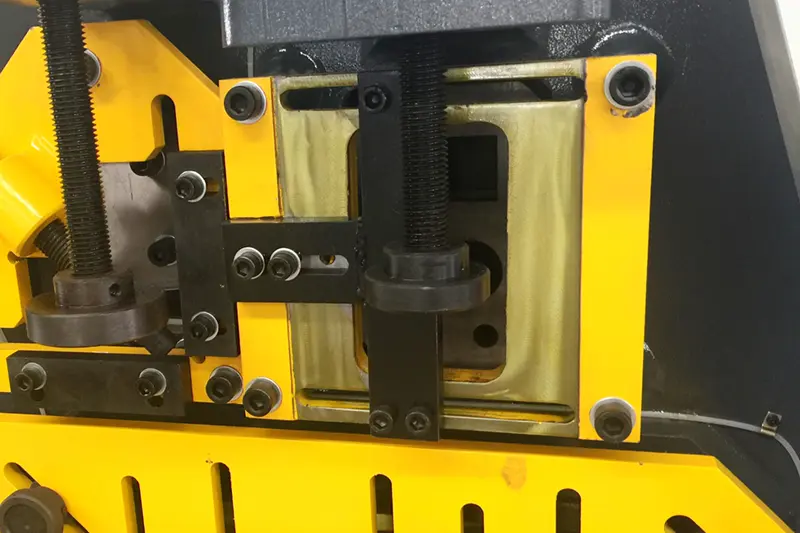

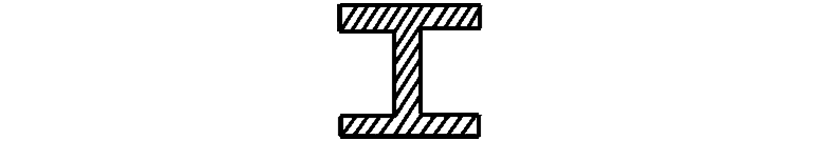

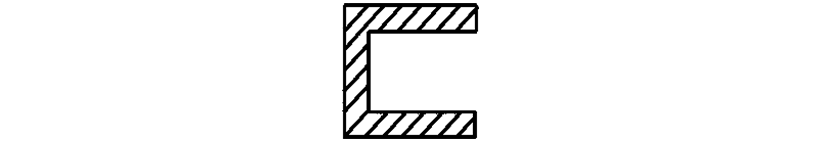

Bars Cutting Station

Standard machines are equipped with blades for cutting U-sections. The edges are held by efficient jaws, ensuring the equipment can be arranged easily at the device without any additional adjustment. Thanks to other equipment, cutting I-section profiles, T-sections, and round and square metal bars is possible.

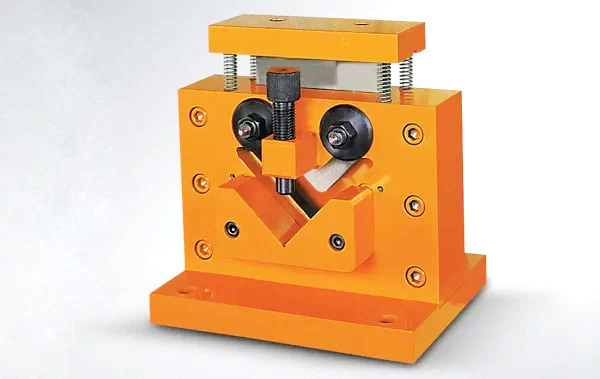

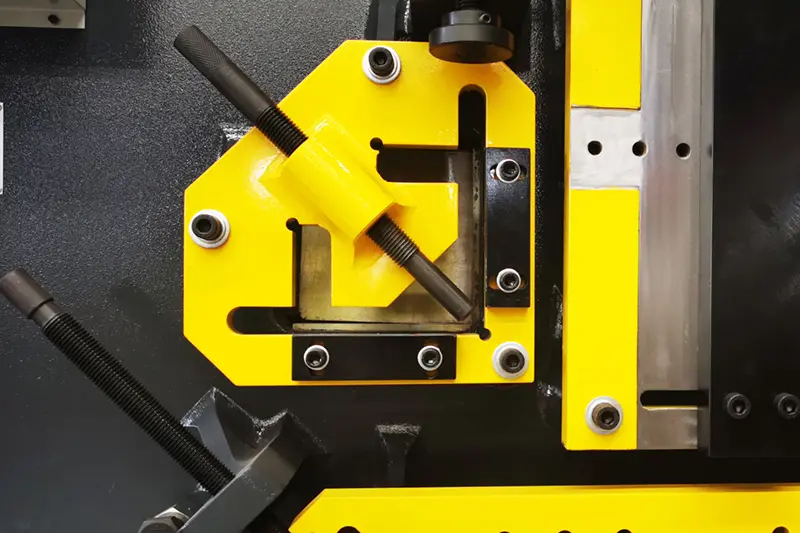

Notching Station of Iron Worker Machine

High Adaptability: With QBH, QCS, and other optical fiber interfaces, it can be adapted to various mainstream laser devices.

Excellent Design: Optimized optical configuration and smooth and efficient airflow design significantly improve cutting quality and efficiency.

Angle Shearing Station

This station enables the cutting of large angles with a capacity ranging from 17 3/4 inches to 35 1/2 inches.

Standard Equipment

REQUEST INFORMATIONElectrics: Schneider Electric - France

Main Motor: Siemens Motor - Germany

Foot Switch: KACON - South Korea

Hydraulic System: Bosch Rexroth - Germany

Oil pump: First/Sunny - USA

Sealing Ring: PARKER - America

Technical Parameter

| Model | Q35Y-12 | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | Q35Y-50 | ||

| Punching Pressure (Tons) | 35 | 60 | 90 | 125 | 160 | 200 | 250 | ||

| Max.Cutting Thickness ofSteel Plates (mm) | 12 | 16 | 20 | 25 | 30 | 40 | 50 | ||

| Material Strength (N/mm2) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤451 | ||

| Cutting Angle Degree | 7° | 7° | 8° | 8° | 8° | 8° | 8° | ||

| Flat Bar Shearing (T X W)(mm) | 12X160 6X300 | 16x250 8x400 | 20x330 10x480 | 25x330 16x600 | 30x335 20x600 | 40x335 30x600 | 50x300 30x750 | ||

| Max. Length of CylinderStroke (mm) | 35 | 80 | 81 | 82 | 83 | 100 | 100 | ||

| The No. of PunchTrips(time/mins) | 10-18 | 11-20 | 12-20 | 8-18 | 6-16 | 6-16 | 6-12 | ||

| Depth of Throat (mm) | 115 | 300 | 355 | 400 | 600 | 530 | 600 | ||

| Punching Depth (mm) | 12 | 16 | 20 | 25 | 28 | 35 | 40 | ||

| Max.Punching Diameter(mm) | 25 | 25 | 30 | 35 | 38 | 40 | 45 | ||

| Main Motor KW | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 18.5 | ||

| Dimension | Length | 950 | 1740 | 1950 | 2355 | 2800 | 2900 | 3200 | |

| Width | 550 | 810 | 900 | 960 | 1050 | 1100 | 1440 | ||

| Height | 1800 | 1830 | 1950 | 2090 | 2450 | 2500 | 2500 | ||

| Weight (KGS) | 1000 | 1800 | 2550 | 4200 | 6500 | 7500 | 120000 | ||

| Round Bar |  |

35 | 45 | 50 | 60 | 65 | 70 | 80 | |

| Square Bar |  |

30x30 | 40x40 | 50x50 | 50x50 | 55x55 | 60x60 | 65x65 | |

| Equal Angle | 90° Shearing |  |

86x86x8 | 120x120x12 | 140x140x12 | 160x160x14 | 180x180x16 | 200x200x18 | 200x200x18 |

| 45° Shearing | 50x50x5 | 70x70x10 | 60x60x6 | 80x80x8 | 80x80x10 | 100x100x10 | |||

| T-Bar | 90° Shearing |  |

125x125x12 | 140x140x12 | 160x160x14 | 180x180x16 | 200x200x18 | 200x200x18 | |

| 45° Shearing | 60x60x8 | 70x70x10 | 80x80x10 | 80x80x10 | 100x100x10 | 120x120x12 | |||

| I Beama |  |

120x74x5 | 160x88x6 | 200x102x9 | 280x124x10.5 | 300x130x13 | 320x130x13 | ||

| C Channel |  |

120x53x5.5 | 160x63x6.5 | 200x75x9 | 280x86x11.5 | 300x89x11.5 | 320x92x12 | ||

Product Video

Q35Y Series

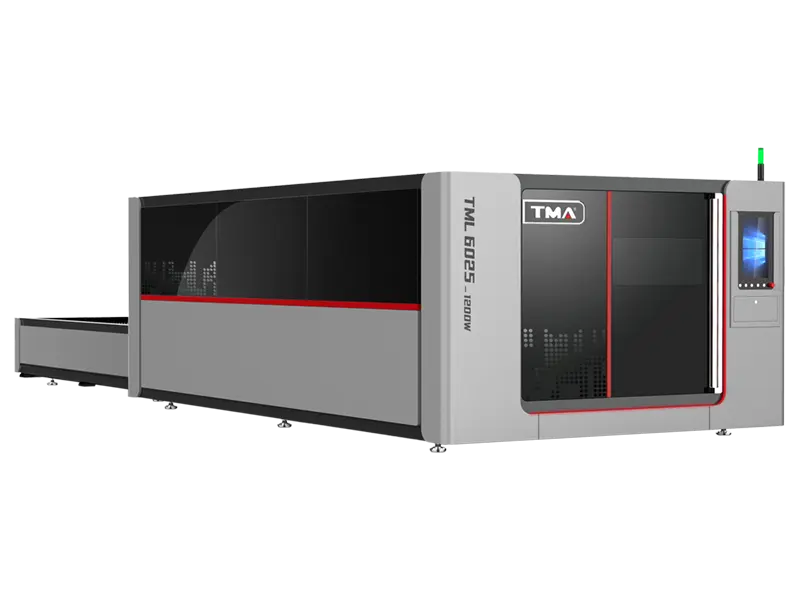

Related Products

Service Advantage

Excellent Processing Equipment

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Tailor-made Solutions

According to your needs and circumstances, reasonable complete equipment solutions and knowledge training can be customized for you.

Super Cost-effective

The company has excellent production environment conditions, complete production process equipment, mature production and manufacturing system, and rich production and manufacturing experience.

Perfect After-sales System

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Qualification

Leave a message online

If you are interested in our company's products, please fill in the relevant information on this page and submit. A staff member will contact you in time, or please call us directly.