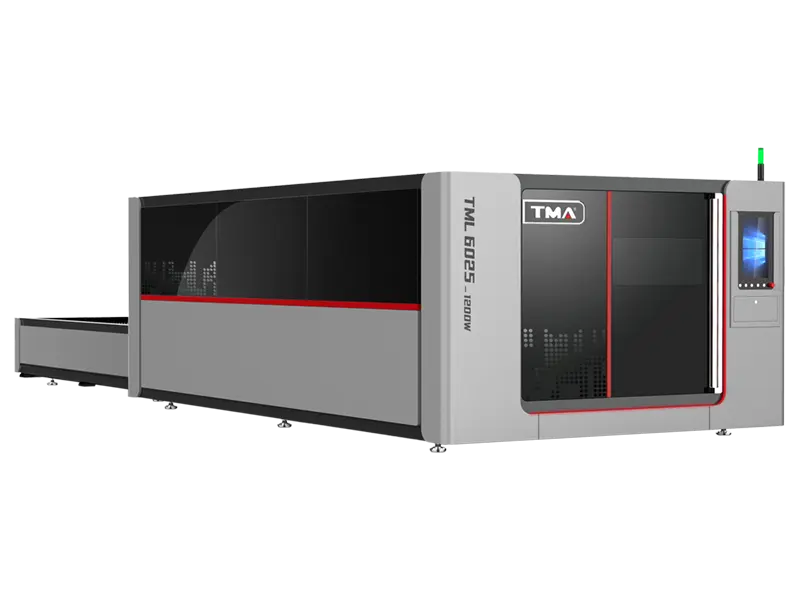

Laser Cutting Machine

Tube Laser Cutting Machine

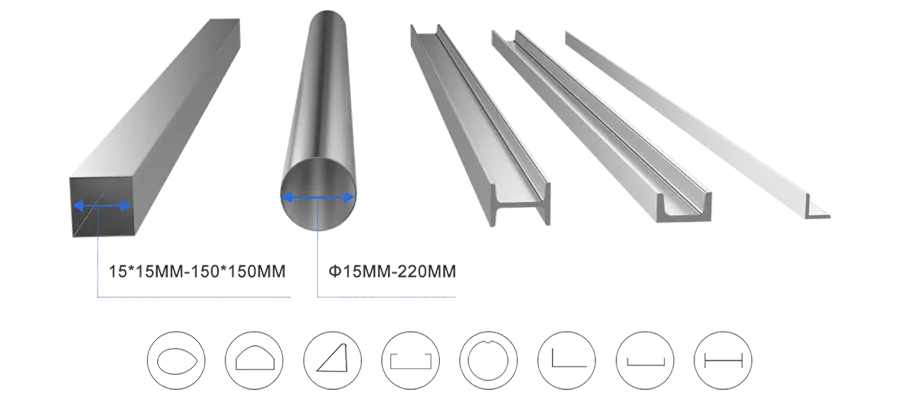

The best laser tube cutting machine with a fiber laser source is used to cut lines & holes on square, round, rectangular, and oval metal tubes, pipes, and profiles; now, the affordable fiber laser tube cutter is for sale at a low price.

Introduction to Configuration

The Pipe Clamping Range is Wide

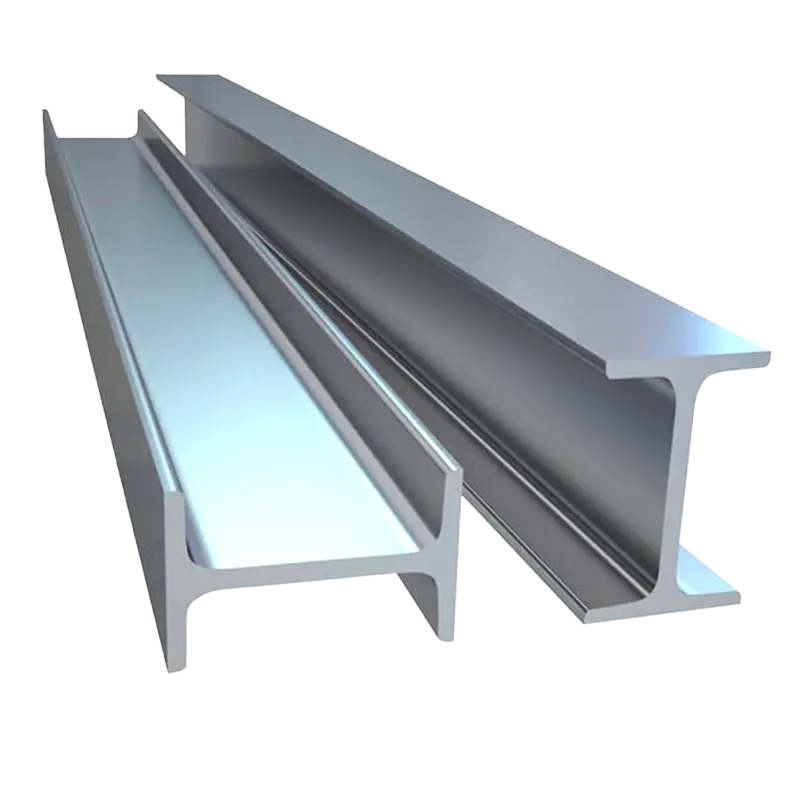

The pipe clamping range of the laser cutting machine is vast, the Round tube is φ10-φ10, and the square tube side length is 10 * 10mm-220mm * 220mm. Support the cutting of various shapes of pipe materials, such as I-beam, channel steel, angle steel, elliptical pipe, waste pipe, multi-deformed pipe, Etc.

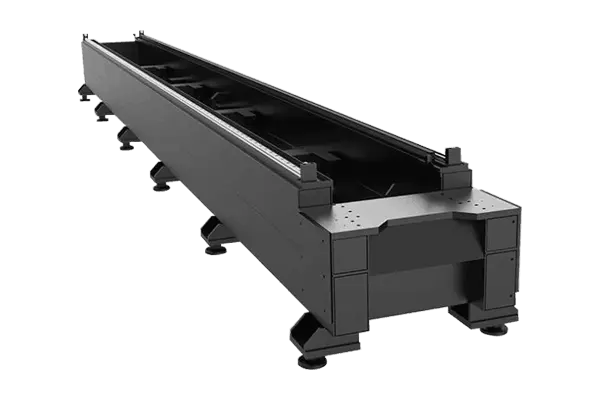

Integrated Machine Bed

The unique industrial structure design gives sheet metal laser cutting machines maximum stability, higher vibration resistance, and damping quality. The compact spacing of 650mm ensures the agility of the chuck and stability during high-speed driving.

Pneumatic roller support

When the Tube&Plate Sheet Metal Laser Cutting Machine works, it can fix the pipe and effectively solves the deformation problem in the cutting operation of the long line.

Tubepro tube cutting and Plate Cutter software

TML tube and plate laser cutting machine equipped with FSCUT3000S pipe cutting system, and FSCUT2000 Plate Cutting System, which supports high-precision and high-efficiency cutting of square pipes, round pipes, racetrack-shaped and oval-shaped stretched lines, as well as angle steel and channel steel.

Wide Processing Range, Can Cut a Variety of Tubes

Tube and plate sheet metal laser cutting machine can process a wide range of tube sizes: round tube diameter ø15mm-ø220mm, square tube side length 15*15-150*150mm; With a 3D laser cutting head, it can easily cut H steel, I-beam, and angle steel, channel steel, and other profiles, as well as drop-shaped and concave shaped tubes.

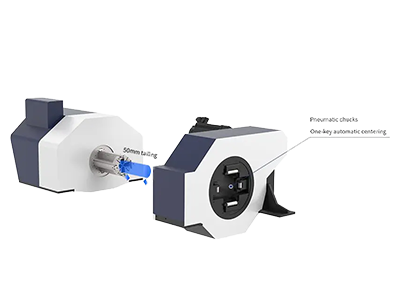

Double Pneumatic Chucks, Ultra-short Tailing

The front and rear of laser cutting machine chucks are featured by automatic centering and dual-driven rotation, keeping them synchronous. The front chuck is full-stroke, and cutting tailing is further shortened to 50mm by front chuck avoidance cutting.

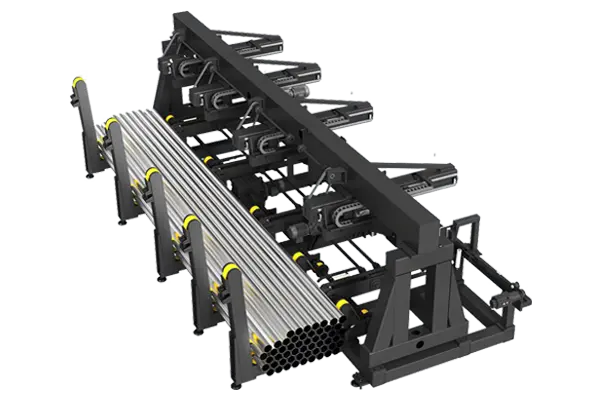

Automatic Loading Equipment(Optional)

◐ Tubes are usually loaded to material laying area by transmission mechanism of which limiting device can make tubes in order.

◐ Tubes are clamped by 6 loading rollers that need no reset in a loading cycle, resulting in less waiting time and high cutting efficiency.

Application Materials of laser cutting machine

TML-6000 sheet metal laser cutting machine can cut carbon steel, stainless steel, aluminum alloy, galvanized sheet, titanium alloy, manganese alloy, Etc. The device is widely used in metal tube processing, auto parts manufacturing, electrical manufacturing, elevator manufacturing, petroleum machinery, food machinery, and decorative advertisements.

Standard Equipment

REQUEST INFORMATIONIPG Fiber Laser Welding - Germany

MAX Fiber Laser Welding - China

Raycus Fiber Laser Welding - China

Technical Parameter

| TYPE | 3015 | 4015 | 4020 | 6015 | 6020 | 6025 | 8025 |

| Processing Gange | 3000mm*1500mm | 4000mm*1500mm | 4000mm*2000mm | 6000mm*1500mm | 6000mm*2000mm | 6000mm*2500mm | 8000mm*2500mm |

| Laser Power | 1500W / 3000W / 6000W / 12000W / 24000W / 30000W | ||||||

| X-Axis Travel | 1525 | 1525 | 2025 | 1525 | 2025 | 2525 | 2525 |

| Y-Axis Travel | 3025 | 4025 | 4025 | 6025 | 6025 | 6025 | 8025 |

| Z-Axis Travel | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Positioning Accuracy | ±0.05mm/m | ||||||

| Repeated Positioning Accuracy | ±0.03mm/m | ||||||

| Maximum Linkage Speed | 100m/min | ||||||

| Maximum Acceleration | 1.5G | ||||||

Product Video

Related Products

Service Advantage

Excellent Processing Equipment

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Tailor-made Solutions

According to your needs and circumstances, reasonable complete equipment solutions and knowledge training can be customized for you.

Super Cost-effective

The company has excellent production environment conditions, complete production process equipment, mature production and manufacturing system, and rich production and manufacturing experience.

Perfect After-sales System

The 7*24-hour service hotline responds promptly to ensure the efficiency of every customer's use; the product has a one-year warranty and a one-stop service for lifetime maintenance.

Qualification

Leave a message online

If you are interested in our company's products, please fill in the relevant information on this page and submit. A staff member will contact you in time, or please call us directly.